Aftermarket solid shifter?

- Thread starter TheNuker

- Start date

DCMoney

Goblin Guru

Awesome, you're designing around the F23 shifter, any reason why this wont work on the F23 and F35?Confidence is high. It’s far from perfect but it’s a very good start.

I had started my own dedicated design similar to factory five. However when I found this I had to give a try, as I’m not even sure I could buy the raw aluminum for what that thing costs.

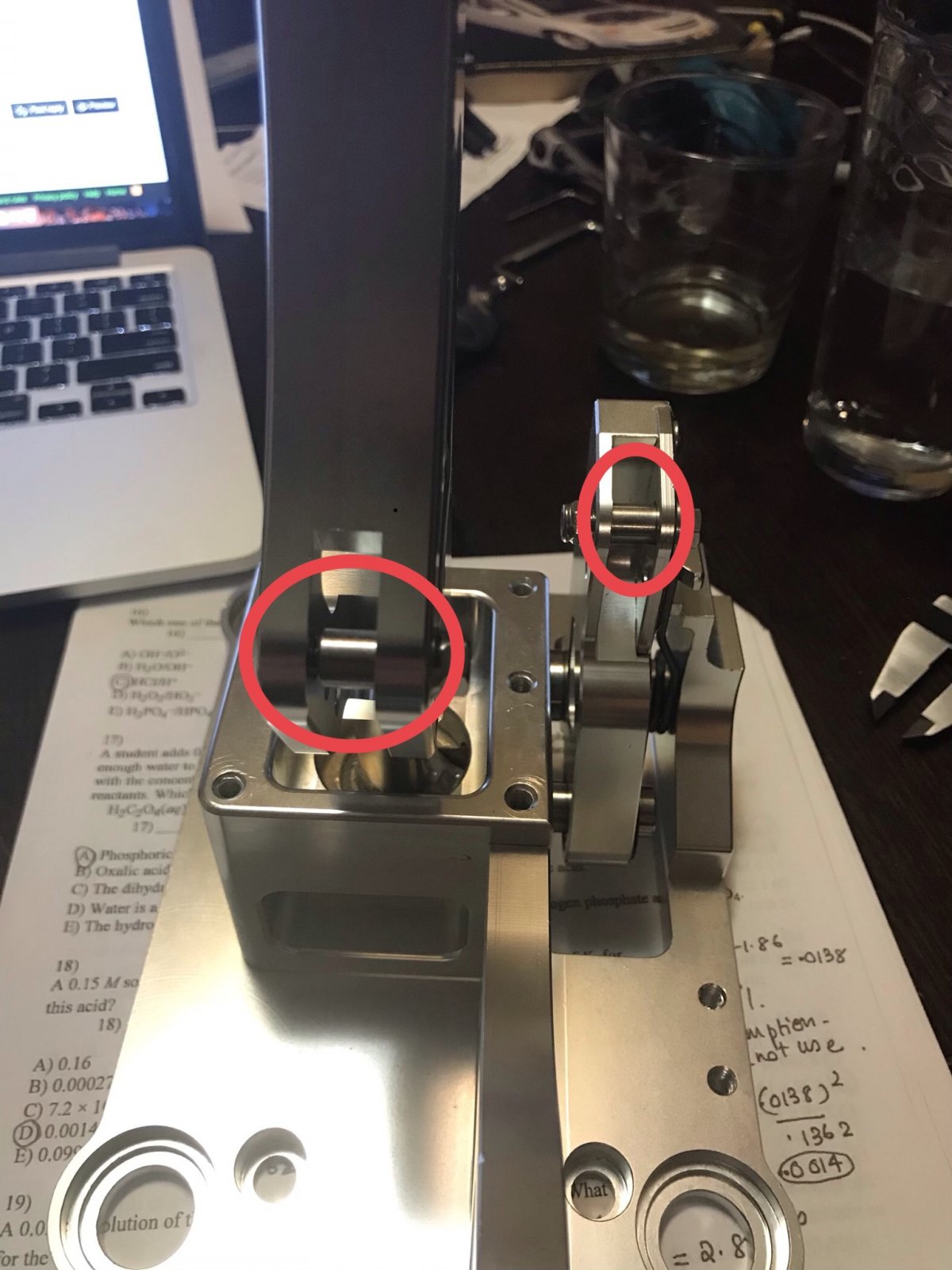

It’s a copy of the Ktuned RSX shifter. Brass bushings and everything. I’m going to add additional set screws to fine tune the tension etc etc etc.

If this works as well as I expect it to it could be a very reasonably priced upgrade.

Ross

Goblin Guru

If you weld a flat plate above shifter 1 (in blue), then you could move the cable attachment point up to the red circle, it would reverse the left/right movement. The black cross is a measurement line. The distance from the current cable attach point to the center cross pivot point could be extended that same amount, above the current pivot point to the red attach point.#1 is left/right, #2 is fwd/bkwdView attachment 10392

Of course, you could just cut the lower attach point off, and weld it up higher.

JSATX

Goblin Guru

It should work with bothAwesome, you're designing around the F23 shifter, any reason why this wont work on the F23 and F35?

JSATX

Goblin Guru

Yes that would be a good way. I’ll try and take that linkage off tomorrow, I don’t remember how it’s attached.If you weld a flat plate above shifter 1 (in blue), then you could move the cable attachment point up to the red circle, it would reverse the left/right movement. The black cross is a measurement line. The distance from the current cable attach point to the center cross pivot point could be extended that same amount, above the current pivot point to the red attach point.

View attachment 10393

Ross

Goblin Guru

No reason. Same logic would work on our F35.Awesome, you're designing around the F23 shifter, any reason why this wont work on the F23 and F35?

Ross

Goblin Guru

Or add a shaft on the other side, and mount it vertically.Pops off easy. Def thinking this is the way to go, thanks Ross.

View attachment 10394

JSATX

Goblin Guru

Didn't do much today, but there are four problems to solve.

1) weld lever arm to trans lever and install new stud. No big deal.

2) Flipping the arm to the other side of the pivot causes the shift cables at the back of the transmission to be completely out of line. Will have to make a whole new mount for cables.

3) the distance from the cable locknuts to the end of the shift cable is about 9.25” in neutral position. RSX distance from cable mount to shift arm is only 6”. Will have to remove built in cable mounts from shifter and weld new ones to tunnel cover.

4) RSX cables have built in eyelets on the end of the cable. Really specific size. Looked everywhere and nothing is popping up. The bore diameter is 8mm and the slot is only 8mm wide so normal female heim joints won’t work. May end up using more ball studs attached to the side, although I would prefer to use the slot.

1) weld lever arm to trans lever and install new stud. No big deal.

2) Flipping the arm to the other side of the pivot causes the shift cables at the back of the transmission to be completely out of line. Will have to make a whole new mount for cables.

3) the distance from the cable locknuts to the end of the shift cable is about 9.25” in neutral position. RSX distance from cable mount to shift arm is only 6”. Will have to remove built in cable mounts from shifter and weld new ones to tunnel cover.

4) RSX cables have built in eyelets on the end of the cable. Really specific size. Looked everywhere and nothing is popping up. The bore diameter is 8mm and the slot is only 8mm wide so normal female heim joints won’t work. May end up using more ball studs attached to the side, although I would prefer to use the slot.

Last edited:

DCMoney

Goblin Guru

That's awesome, do you think it was worth the effort to not use the reversing cranks?

Understand directly connecting to the shifter removes a few stacking tolerances and play, but removing the plastic socket joins and going to a rod end that connects to the new shifter seems like it would work, may have to shorten or lengthen the tie rods. Route out a plate to match the existing bolt pattern plus a few holes for the bolt pattern of the new assembly and go. No modifying the transmission mount, no new cable holder.

Might be over simplifying it. When I get back from vacation going to buy one of these shifter assemblies.

Does it have a reverse lockout?

Understand directly connecting to the shifter removes a few stacking tolerances and play, but removing the plastic socket joins and going to a rod end that connects to the new shifter seems like it would work, may have to shorten or lengthen the tie rods. Route out a plate to match the existing bolt pattern plus a few holes for the bolt pattern of the new assembly and go. No modifying the transmission mount, no new cable holder.

Might be over simplifying it. When I get back from vacation going to buy one of these shifter assemblies.

Does it have a reverse lockout?

JSATX

Goblin Guru

the Getrag has an internal reverse lockout. There is not one externalThat's awesome, do you think it was worth the effort to not use the reversing cranks?

Understand directly connecting to the shifter removes a few stacking tolerances and play, but removing the plastic socket joins and going to a rod end that connects to the new shifter seems like it would work, may have to shorten or lengthen the tie rods. Route out a plate to match the existing bolt pattern plus a few holes for the bolt pattern of the new assembly and go. No modifying the transmission mount, no new cable holder.

Might be over simplifying it. When I get back from vacation going to buy one of these shifter assemblies.

Does it have a reverse lockout?