BAR-AIR

Well-Known Member

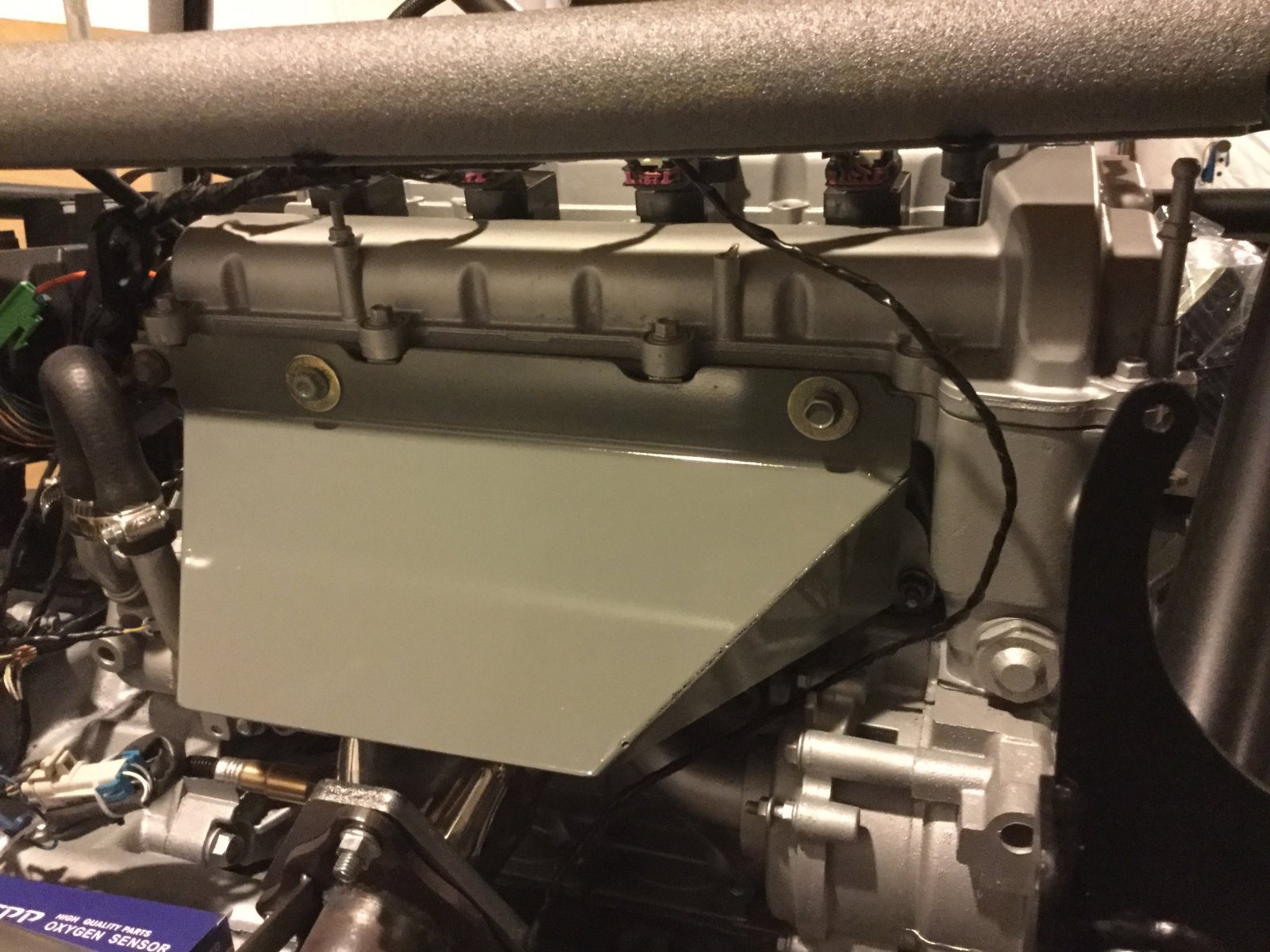

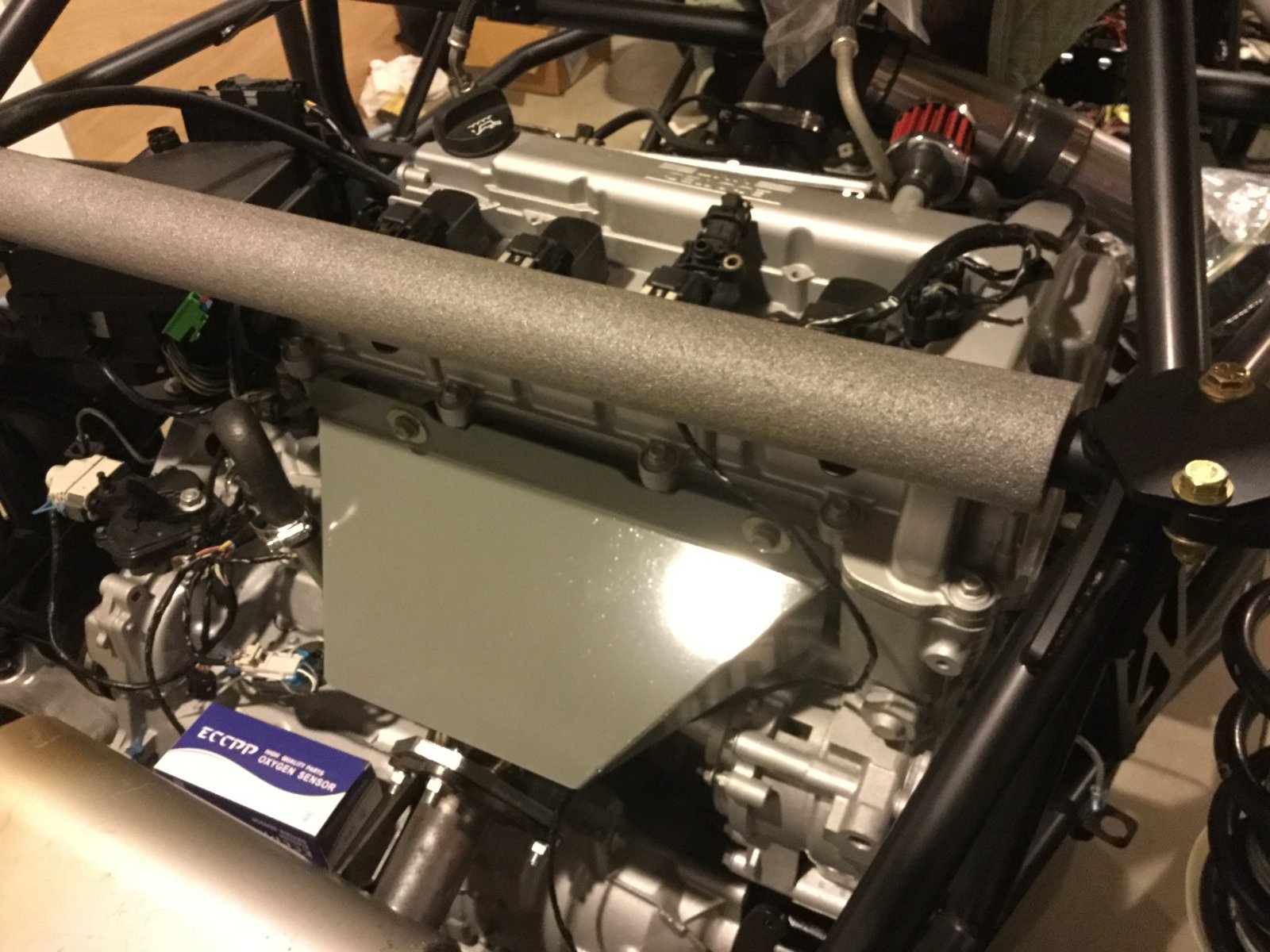

Here is the new heat shield for after market headers....

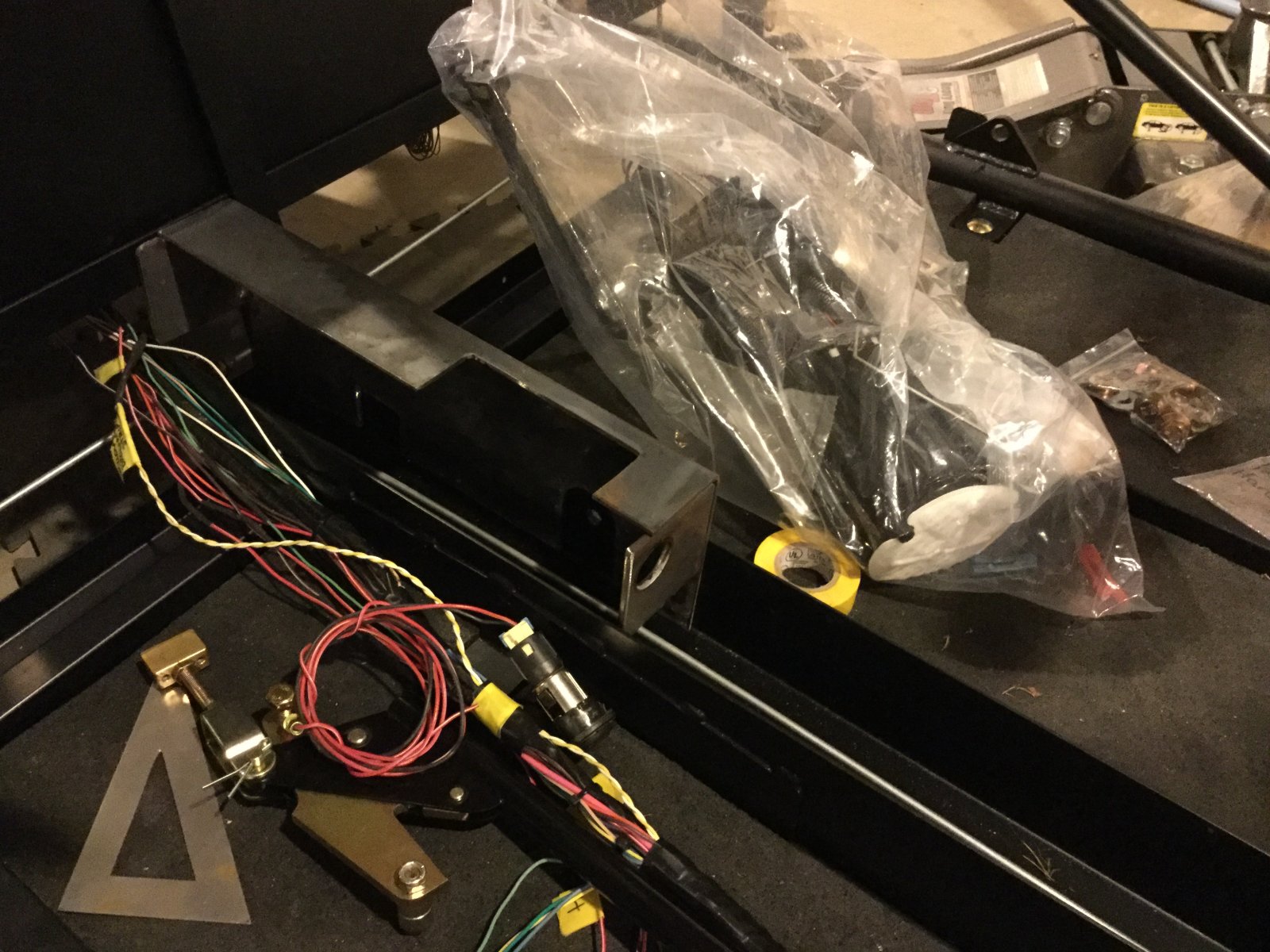

Here is the beginning of the welded new emergency brake mount it is a one sided mount (with the brake handle offset to the drivers side) so that you can still get inside to adjust the cables. The 1" circular hole is for one of the 12v power supplies. There will be a bent cover plate to finish the passengers side.

Here is the beginning of the welded new emergency brake mount it is a one sided mount (with the brake handle offset to the drivers side) so that you can still get inside to adjust the cables. The 1" circular hole is for one of the 12v power supplies. There will be a bent cover plate to finish the passengers side.