Jareth

Goblin Guru

With my 30 year career with Creo and SolidWorks some might have thought I might have already had a 3D printer, but it was not until yesterday that I got one

It’s a Creality Ender 3 V2, it only has a “220 X 220 X 250“ print area so if I want to make some of the larger parts I will need to learn about the tolerance it’s capable of in creating dovetail joints.

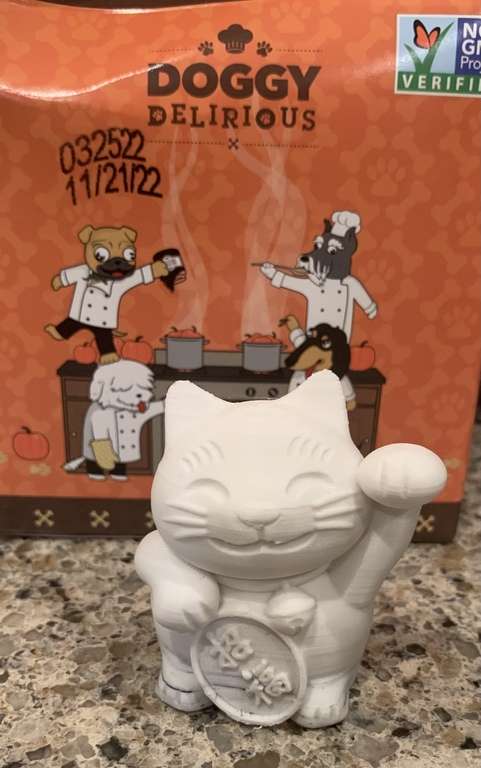

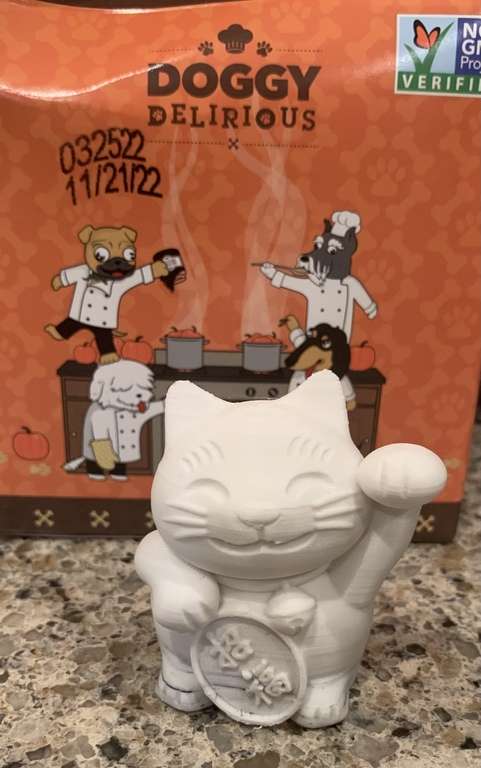

Here is a quick sample. Not so sure about quick though, it took 3 hours.

It’s a Creality Ender 3 V2, it only has a “220 X 220 X 250“ print area so if I want to make some of the larger parts I will need to learn about the tolerance it’s capable of in creating dovetail joints.

Here is a quick sample. Not so sure about quick though, it took 3 hours.