Build update:

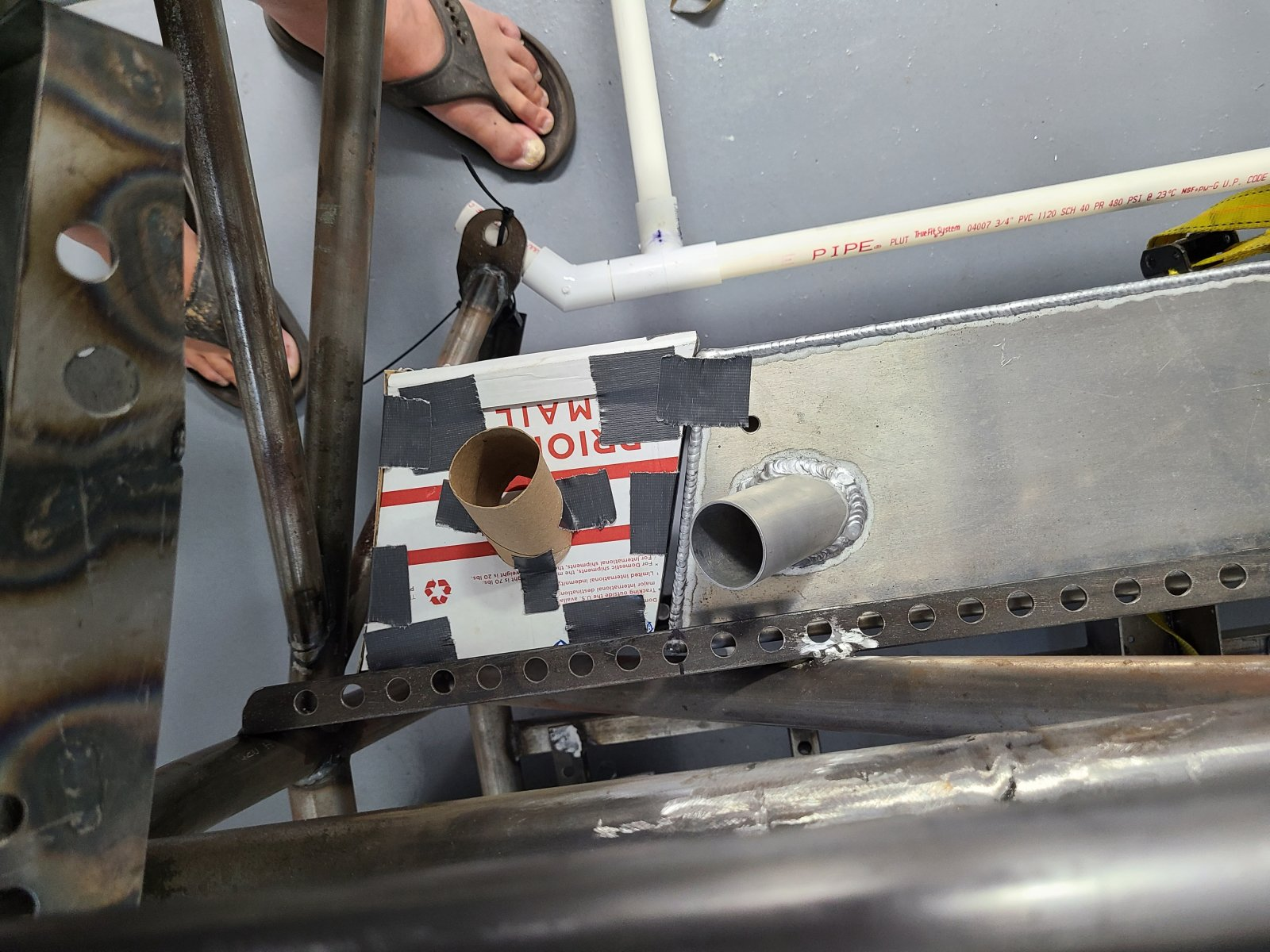

So after all the measuring, cutting, drilling, grinding, making certain that everything is straight, square and plumb - and the final welding of all triangulation bars to stiffen the frame to my satisfaction - I have finally finished the major modifications to my DF frame. Its been a long time coming, about 2 1/2 years, of analyzing, designing, and fabrication (with several turnbacks to start over).

Yep, I added some weight to both the front and rear, but it is now as strong as it can be made using the minimum number of triangulation pieces (10 total). My inner engineer is now satisfied with the end result. There are still numerous small brackets and tabs to be added (nothing complex), which will be worked when I finally start assembling the dry mockup - which is hopefully not too far off in the future.

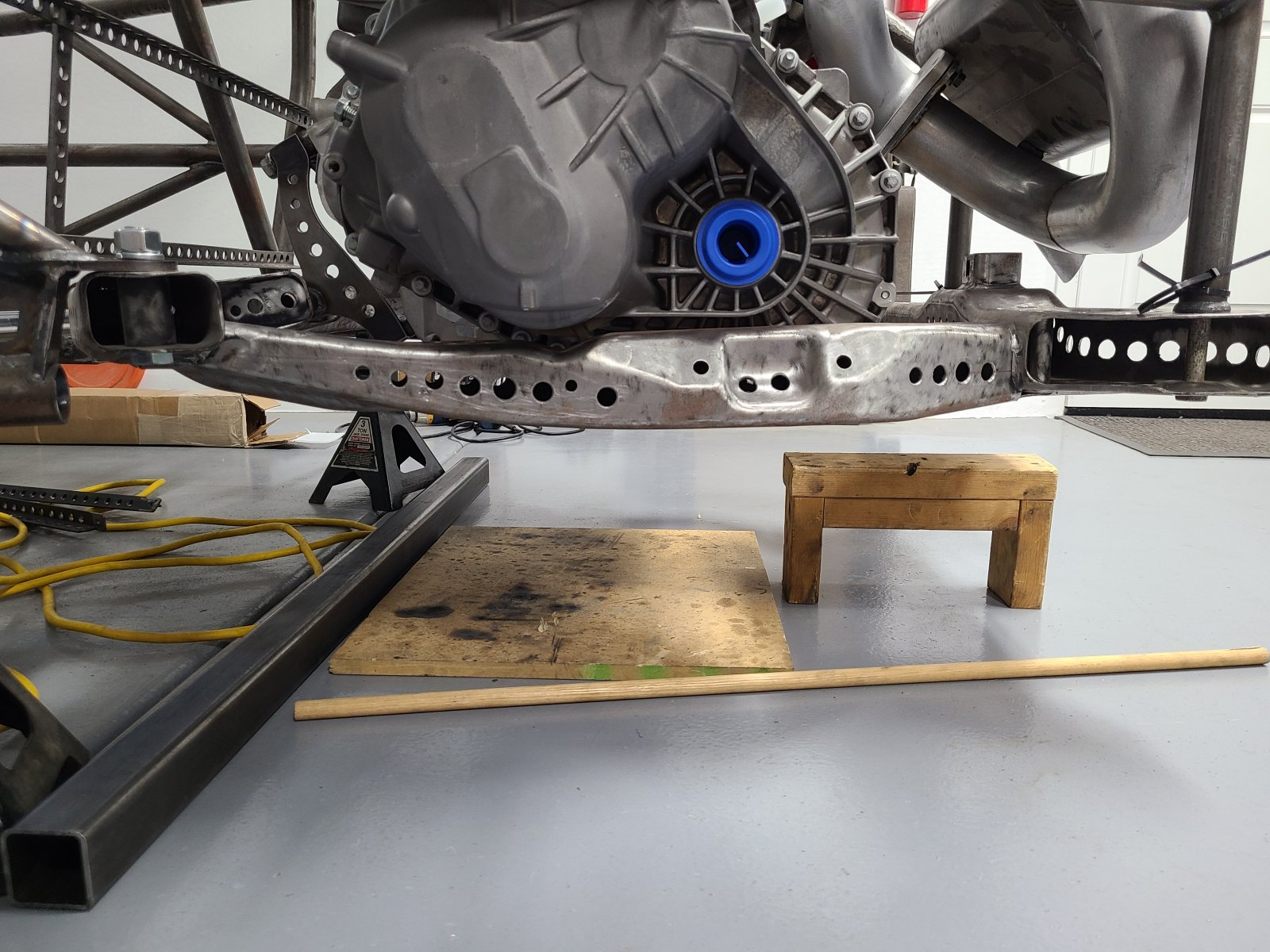

However, the rear suspension project is in full swing, which is the long pole in the tent. Waiting on materials to show up so it can continue. I did decide to fabricate new aluminum uprights, rather than try to use the Cobalt uprights:

The machining of these blocks will be a chore and I hope I don't turn these into expensive scrap.

Another item that is slowing things down is locating correct drive axles. I cannot fabricate the UCAs/LCAs until I have the axle lengths. The F40 requires a shorter (by almost 2 inches) axle on the driver's side. I did not purchase the ZZP F40 kit with the axle, so I'm trying to source one with no luck. ZZP or their supplier does not sell this axle outright and a custom axle is $1200 for just the driver's side axle.

If someone has insight to locating this axle, please let me know.

So, plan B is to locate the shortest GM axle for the driver's side, with the same spline counts and shaft nose geometry, and then locate a passenger's side axle that is 2 inches longer. Example: driver side is 22.5 inches, the passenger side would be 24.5 inches. I may need to buy several axles to swap stub ends around to get the correct splines and nose dimensions. The Double Bonus for going this way is the rear track will be wider to correct for the reported narrower stance at the rear and the UCAs will be longer to help with the camber gain geometry.

More to come. Keep it Squatchy!