Lonewolf170

Active Member

Ended up taking the bolt out of the top of the steering column and separating the shaft to drop the subframe. No idea how that bolt got in there.

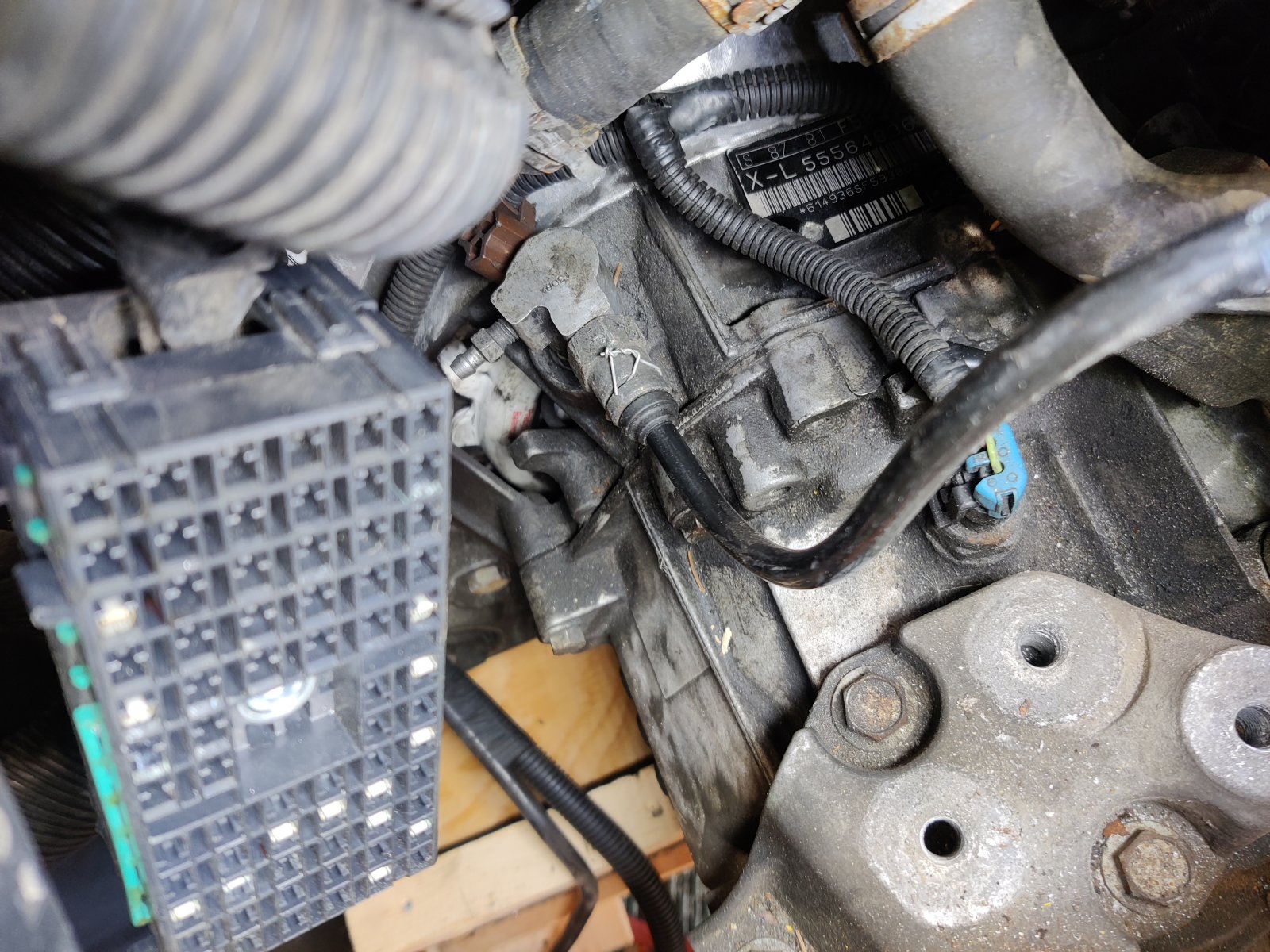

I've dropped the engine but have this one wire from the transmission to the dash it looks like. Do I just pull it out of the transmission? It is the one with the wire wrap on it.

I've dropped the engine but have this one wire from the transmission to the dash it looks like. Do I just pull it out of the transmission? It is the one with the wire wrap on it.