newbtrying

Active Member

Hey all, my name is Riley and I'm a 27 YO in KY (Montana as of next month). I'm a perfusionist by occupation, which means I start and stop hearts in the operating room so the cardiac surgeon can operate. You should note that my education is far from any of the inner workings of vehicles, so I'm learning a lot on the go. My dad is a diesel mechanic, so I've picked up just enough knowledge from him to turn some wrenches and successfully complete projects as long as there is a youtube guide

Anyway, many of you have answered my questions in other forum threads, but I've not posted a build log yet. It's finally time even though I have missed A LOT of the developments. I bought my 2007 SS donor car, received the first stage, completed tear down of the donor, and rewired my harness all within a month or so, but I hit a HUGE speedbump when, on a suspicion, I tore into the block and found blown pistons and cylinder damage that required a sleeve change. At that point, I chose to upgrade a lot of things *while I am in there*. A few items included new sodium-filled valves, titanium keepers and caps, heavier valve springs, ZZP stage 2 cams, ZZP Zero balance shafts, Cloyes timing chain kit, ZZP timing chain guide, K1 con rods, Racetech 10.5:1 pistons, AEM high flow fuel pump, ZZP basic turbo kit w/ Z57 turbo, F23 swap, and more that I'm forgetting since I made this list off memory.

Because It took over a year for my block to get resleeved (ridiculous, I know), I've forgotten the details of what I did early on. Exhibit A of why I am writing here and now. I have a lot of updates and questions, which I'll number to aid in organization for answering them.

A few days ago, I finally got my engine assembled with all of the upgrades after receiving the newly sleeved block and last night I got the engine mounted in my chassis. I did this in a less conventional way because it was 4 AM, my pregnant wife couldn't be lifting weight, and I had an engine hoist. It worked well! (pics below) I had to take off my ZZP air intake and rotate the compressor housing on the turbo to get the piping over the bar in the rear, but I like how that turned out.

1) I'd like to keep this air intake, but need help brainstorming on ways to secure it so that it does not flop around. (pics below)

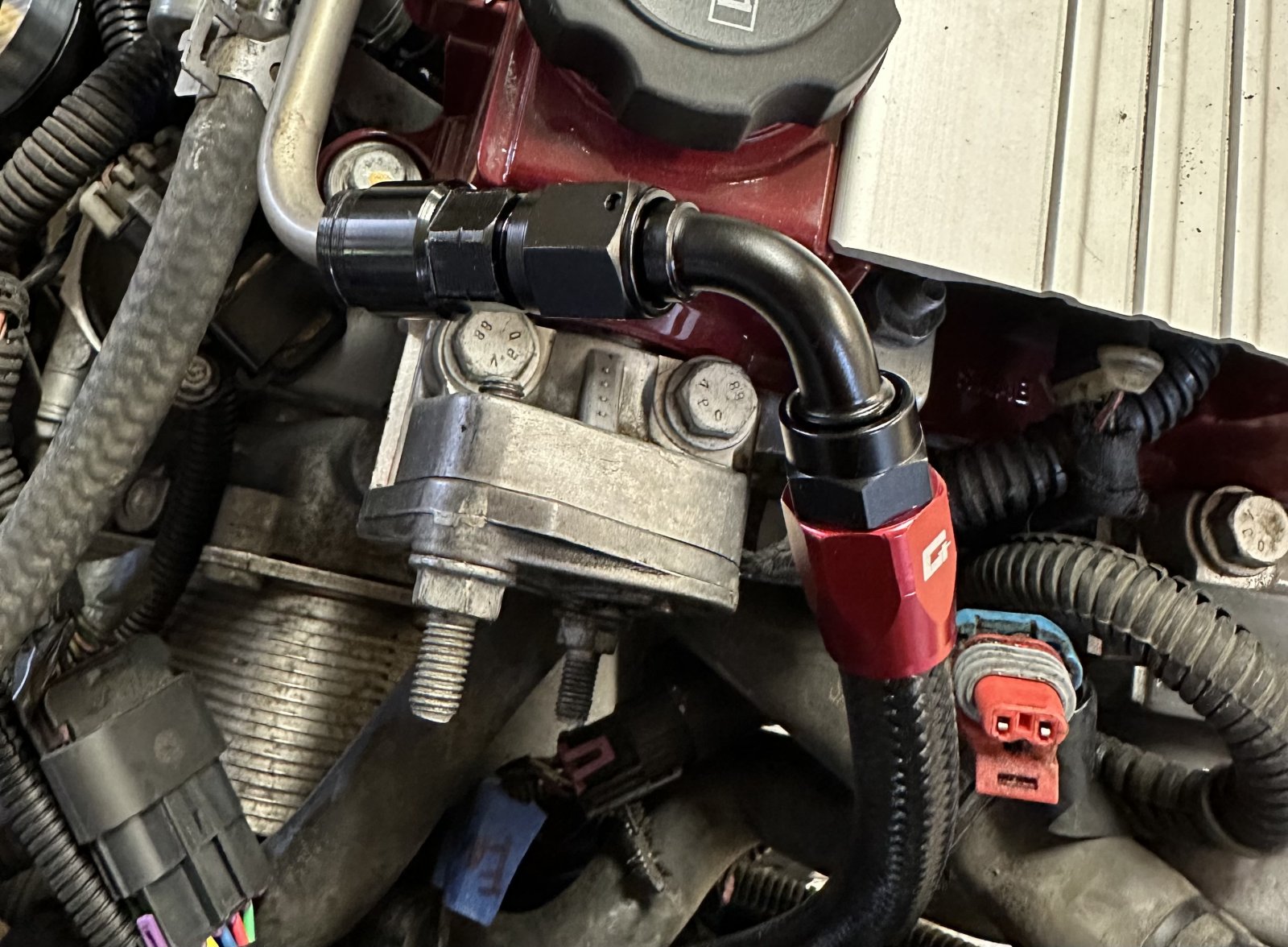

I also chose to use AN6 hose as a fuel line, so I got that installed today. easy peasy. (below)

2) the coolant plumbing on the passenger side, I did a bit differently than intended, I think. In the 7 year old assembly video, It shows the 17" piece of hose being spliced in to the hose that goes through the chassis and again spliced into the bottom of the 60-degree hose that attaches to the head. I did this, but I did not have another aluminum splice that came in the kit, or enough hose clamps to make these splices. I checked the kit list and saw that I received the proper number of clamps and splices, so I assume DF intended me to do this in a different manner, but I can't figure out what that was and this works fine. In the end, I went to the hardware store and picked up a 1-1/4" steel barbed fitting and 2 hose clamps and made the splice to the 60-degree elbow. Here's the question though: How do I secure the hose so that it doesn't rub against the alternator pully? The coated clamp in the baggy with the clamps (in pic) has a tiny hole through it that I know the engine mount bolt will not go through, as the video guide showed. Do I need to buy a different clamp? (2)

And now for some wiring questions: If you don't know what I've got going on (most likely), please give me ideas/instruction on how to diagnose/track down potential issues.

3) On the main harness, I have a pink/white stripe wire bundled with a black (ground?) wire that is labeled intercooler water pump. This branches off near the intercooler pump, but my SS already has the proper connections for this. Do I bundle up these wires and forget about them, or do I need to actually use these? (pic below)

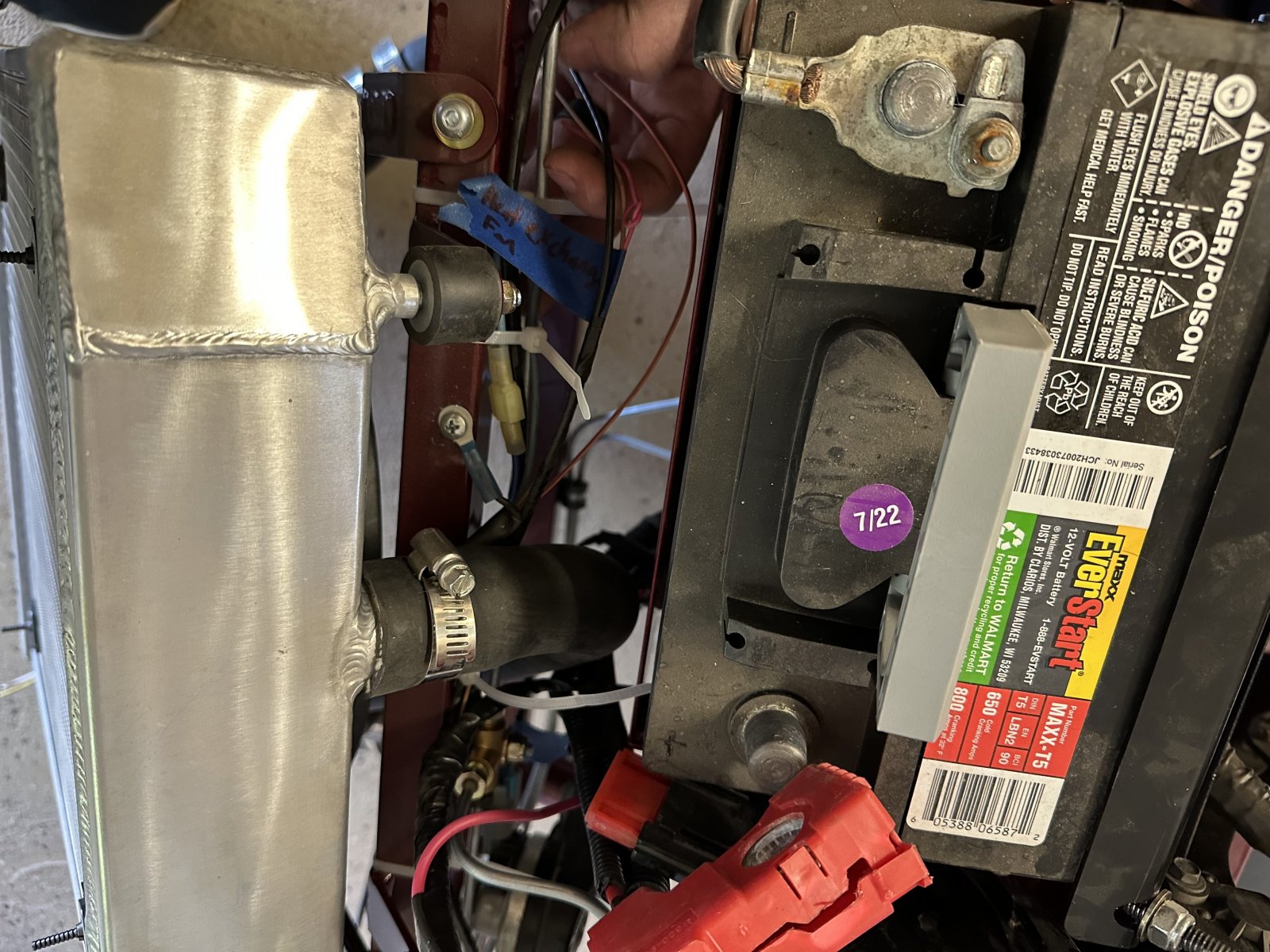

4) there's a bundle of wires that come off of the main harness near my battery box (see pic below) one of these is pink and labeled, "heat exchanger fan", which I think I'll be using to power DF's intercooler heat exchanger fan that mounts near here (I don't have this heat exchanger, but I assume it comes in stage 2 or 3). Is this right? (Pic below)

5) from the bundle just mentioned, I also have a tan wire labeled "Clutch B6 Fuel Pump Extension". This is something I'm very sure/concerned I messed up... If my 1-year recall is working correctly, I followed the video instructions word-for-word and bundled the necessary tan wires and soldered them together, but I think I only had 2 tan wires of the 3 mentioned, so I soldered a long tan extension in as well and you are looking at the end of it in the pic below. I could be way way off base on what I did, but question number 5 is two parts: Am I supposed to have this wire chilling like this, and IF I didn't bridge the intended connection during the harness rework, how do I diagnose the mistake, what wouldn't have power/be hooked up, and will this effect my first start up? (5) (pic below)

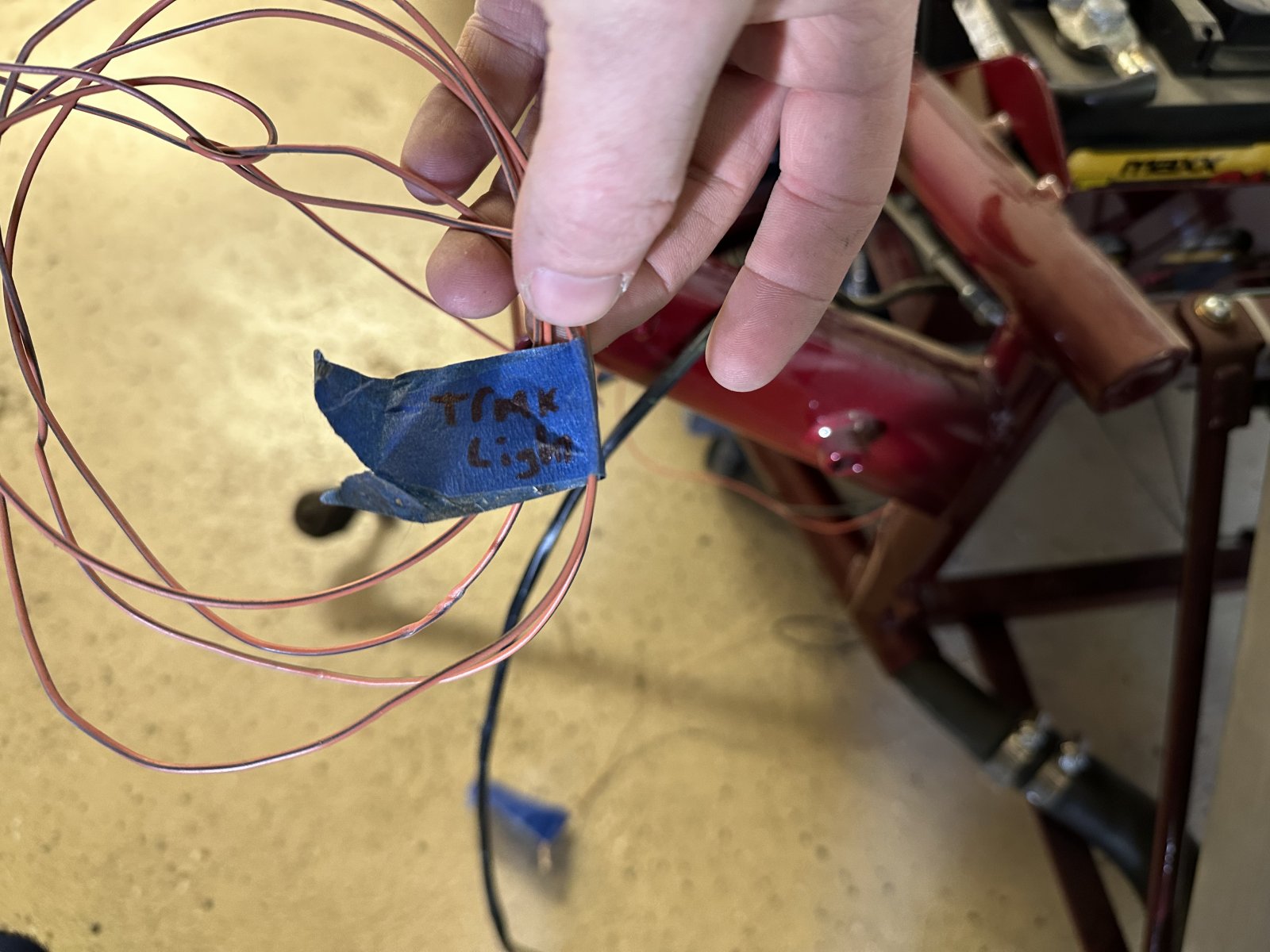

6) still on the same bundle of wires as 4 and 5, I also have a wire labeled, "Trunk light". What do I do with this? (see pic)

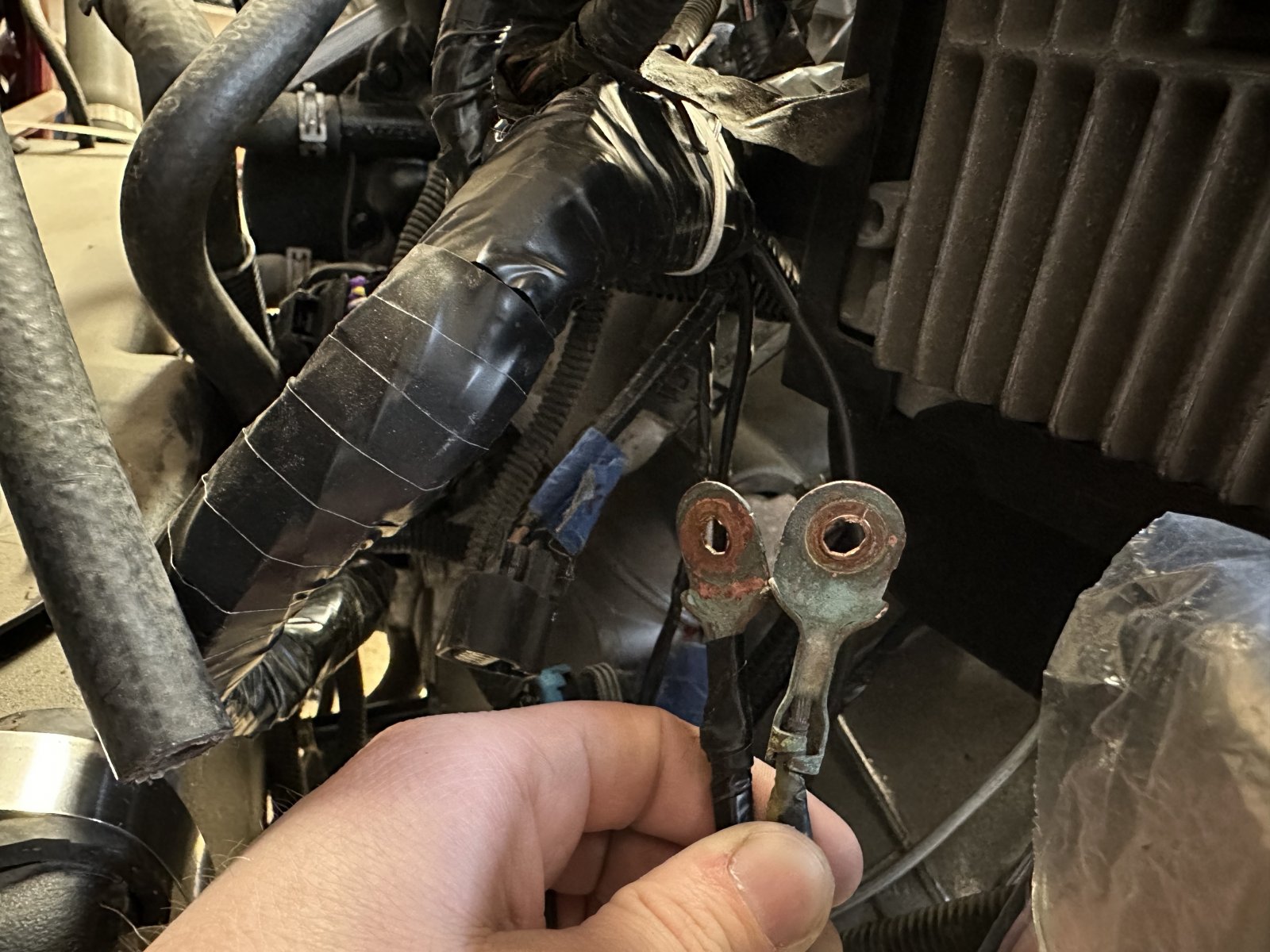

7) in the pic below, I have 2 ground wires that branch off near the fuse box housing. one is long enough to attach to the ground stud on the chassis of the goblin that is located below the fuse box. The other is just short of being able to attach it there. Does the long one go to the chassis and other one go to another location? Or do I need to extend the short one and ground it on the chassis? (7)

In the pic above, you can also see my fuel pump connector, which I somehow made about 3" too short... I'll be extending that in the near future.

In the pic above, you can also see my fuel pump connector, which I somehow made about 3" too short... I'll be extending that in the near future.

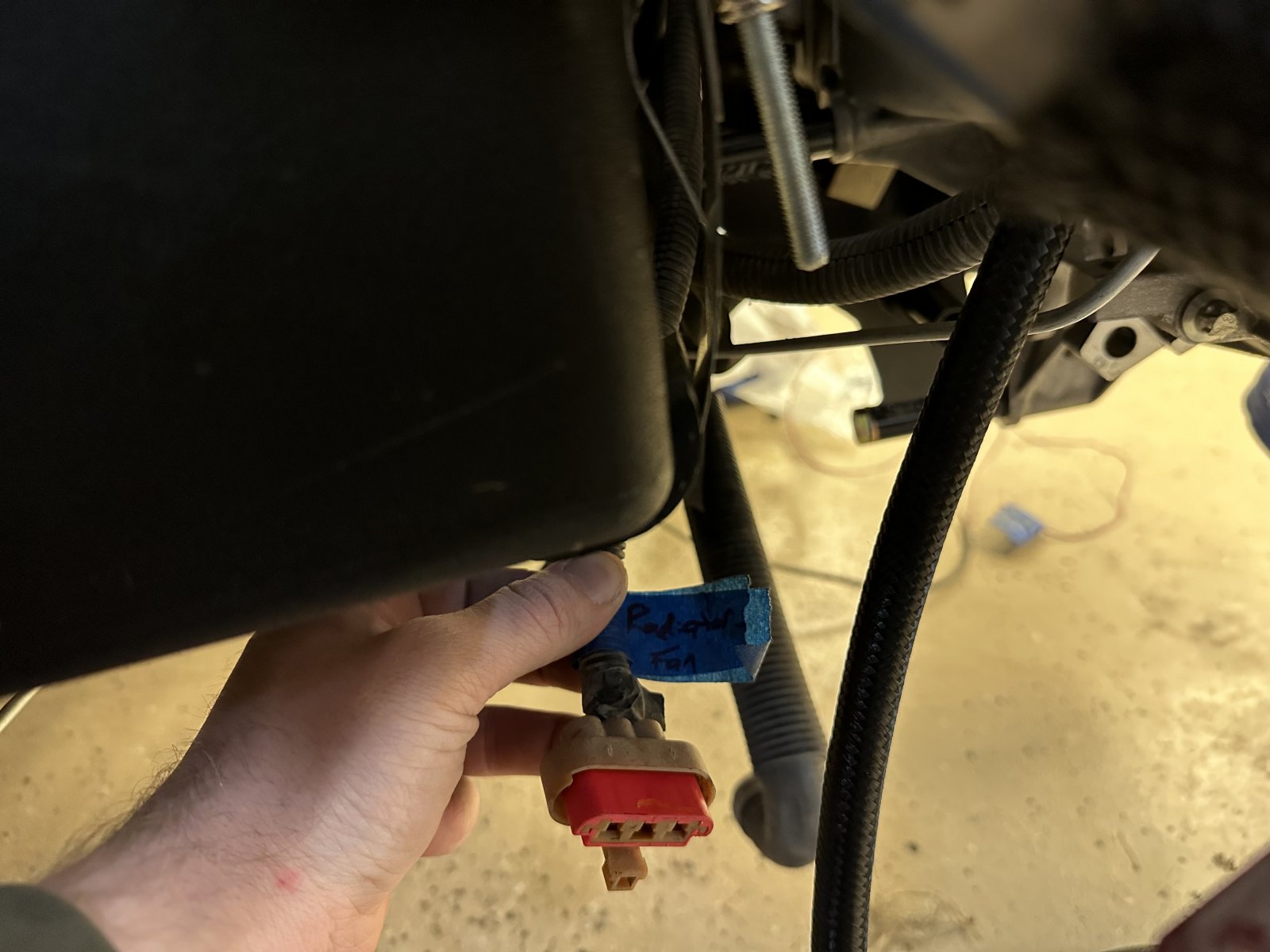

8) On the engine harness, I have a red/tan plug I labeled "radiator fan" over a year ago. Do I just lop this off since I won't be using it, or should I keep it? Or am I totally off base and is it used for something else? (pic below)

So that's my introduction on the build logs, I'll be posting more routinely now. And thanks to anyone who helps me out. I could not do this without you guys, seriously.

Anyway, many of you have answered my questions in other forum threads, but I've not posted a build log yet. It's finally time even though I have missed A LOT of the developments. I bought my 2007 SS donor car, received the first stage, completed tear down of the donor, and rewired my harness all within a month or so, but I hit a HUGE speedbump when, on a suspicion, I tore into the block and found blown pistons and cylinder damage that required a sleeve change. At that point, I chose to upgrade a lot of things *while I am in there*. A few items included new sodium-filled valves, titanium keepers and caps, heavier valve springs, ZZP stage 2 cams, ZZP Zero balance shafts, Cloyes timing chain kit, ZZP timing chain guide, K1 con rods, Racetech 10.5:1 pistons, AEM high flow fuel pump, ZZP basic turbo kit w/ Z57 turbo, F23 swap, and more that I'm forgetting since I made this list off memory.

Because It took over a year for my block to get resleeved (ridiculous, I know), I've forgotten the details of what I did early on. Exhibit A of why I am writing here and now. I have a lot of updates and questions, which I'll number to aid in organization for answering them.

A few days ago, I finally got my engine assembled with all of the upgrades after receiving the newly sleeved block and last night I got the engine mounted in my chassis. I did this in a less conventional way because it was 4 AM, my pregnant wife couldn't be lifting weight, and I had an engine hoist. It worked well! (pics below) I had to take off my ZZP air intake and rotate the compressor housing on the turbo to get the piping over the bar in the rear, but I like how that turned out.

1) I'd like to keep this air intake, but need help brainstorming on ways to secure it so that it does not flop around. (pics below)

I also chose to use AN6 hose as a fuel line, so I got that installed today. easy peasy. (below)

2) the coolant plumbing on the passenger side, I did a bit differently than intended, I think. In the 7 year old assembly video, It shows the 17" piece of hose being spliced in to the hose that goes through the chassis and again spliced into the bottom of the 60-degree hose that attaches to the head. I did this, but I did not have another aluminum splice that came in the kit, or enough hose clamps to make these splices. I checked the kit list and saw that I received the proper number of clamps and splices, so I assume DF intended me to do this in a different manner, but I can't figure out what that was and this works fine. In the end, I went to the hardware store and picked up a 1-1/4" steel barbed fitting and 2 hose clamps and made the splice to the 60-degree elbow. Here's the question though: How do I secure the hose so that it doesn't rub against the alternator pully? The coated clamp in the baggy with the clamps (in pic) has a tiny hole through it that I know the engine mount bolt will not go through, as the video guide showed. Do I need to buy a different clamp? (2)

And now for some wiring questions: If you don't know what I've got going on (most likely), please give me ideas/instruction on how to diagnose/track down potential issues.

3) On the main harness, I have a pink/white stripe wire bundled with a black (ground?) wire that is labeled intercooler water pump. This branches off near the intercooler pump, but my SS already has the proper connections for this. Do I bundle up these wires and forget about them, or do I need to actually use these? (pic below)

4) there's a bundle of wires that come off of the main harness near my battery box (see pic below) one of these is pink and labeled, "heat exchanger fan", which I think I'll be using to power DF's intercooler heat exchanger fan that mounts near here (I don't have this heat exchanger, but I assume it comes in stage 2 or 3). Is this right? (Pic below)

5) from the bundle just mentioned, I also have a tan wire labeled "Clutch B6 Fuel Pump Extension". This is something I'm very sure/concerned I messed up... If my 1-year recall is working correctly, I followed the video instructions word-for-word and bundled the necessary tan wires and soldered them together, but I think I only had 2 tan wires of the 3 mentioned, so I soldered a long tan extension in as well and you are looking at the end of it in the pic below. I could be way way off base on what I did, but question number 5 is two parts: Am I supposed to have this wire chilling like this, and IF I didn't bridge the intended connection during the harness rework, how do I diagnose the mistake, what wouldn't have power/be hooked up, and will this effect my first start up? (5) (pic below)

6) still on the same bundle of wires as 4 and 5, I also have a wire labeled, "Trunk light". What do I do with this? (see pic)

7) in the pic below, I have 2 ground wires that branch off near the fuse box housing. one is long enough to attach to the ground stud on the chassis of the goblin that is located below the fuse box. The other is just short of being able to attach it there. Does the long one go to the chassis and other one go to another location? Or do I need to extend the short one and ground it on the chassis? (7)

8) On the engine harness, I have a red/tan plug I labeled "radiator fan" over a year ago. Do I just lop this off since I won't be using it, or should I keep it? Or am I totally off base and is it used for something else? (pic below)

So that's my introduction on the build logs, I'll be posting more routinely now. And thanks to anyone who helps me out. I could not do this without you guys, seriously.