Mikes Extended, Full Frame Goblin - 2009 Cobalt LS with 135k donor

- Thread starter mike_sno

- Start date

Yes, that was the first things I checked. The fuel rail sits in is place, I would think that means that the injector are also sitting properly.

It could be that the wiring harness is different? I'll check that tomorrow as well.

I just saw that I can reset the fuel trims in vcm scanner and disable the injector individually. That's what I will try tomorrow and see if that feels me narrowing down the failure.

It could be that the wiring harness is different? I'll check that tomorrow as well.

I just saw that I can reset the fuel trims in vcm scanner and disable the injector individually. That's what I will try tomorrow and see if that feels me narrowing down the failure.

Good idea, I have an IR camera.A lazer temperature gun pointed at each exhaust pipe when the engine is running, will tell if you have 1 bad injector, or cylinder.

If you don't have a lazer gun, you can see how long it takes a cold exhaust manifold to get too hot to keep your fingers on.

ah.b.normal

Goblin Guru

Great it was a simple fix!Problem solved. I looked at the not working cylinder and saw that the insulator came out and was stuck on the old injector.

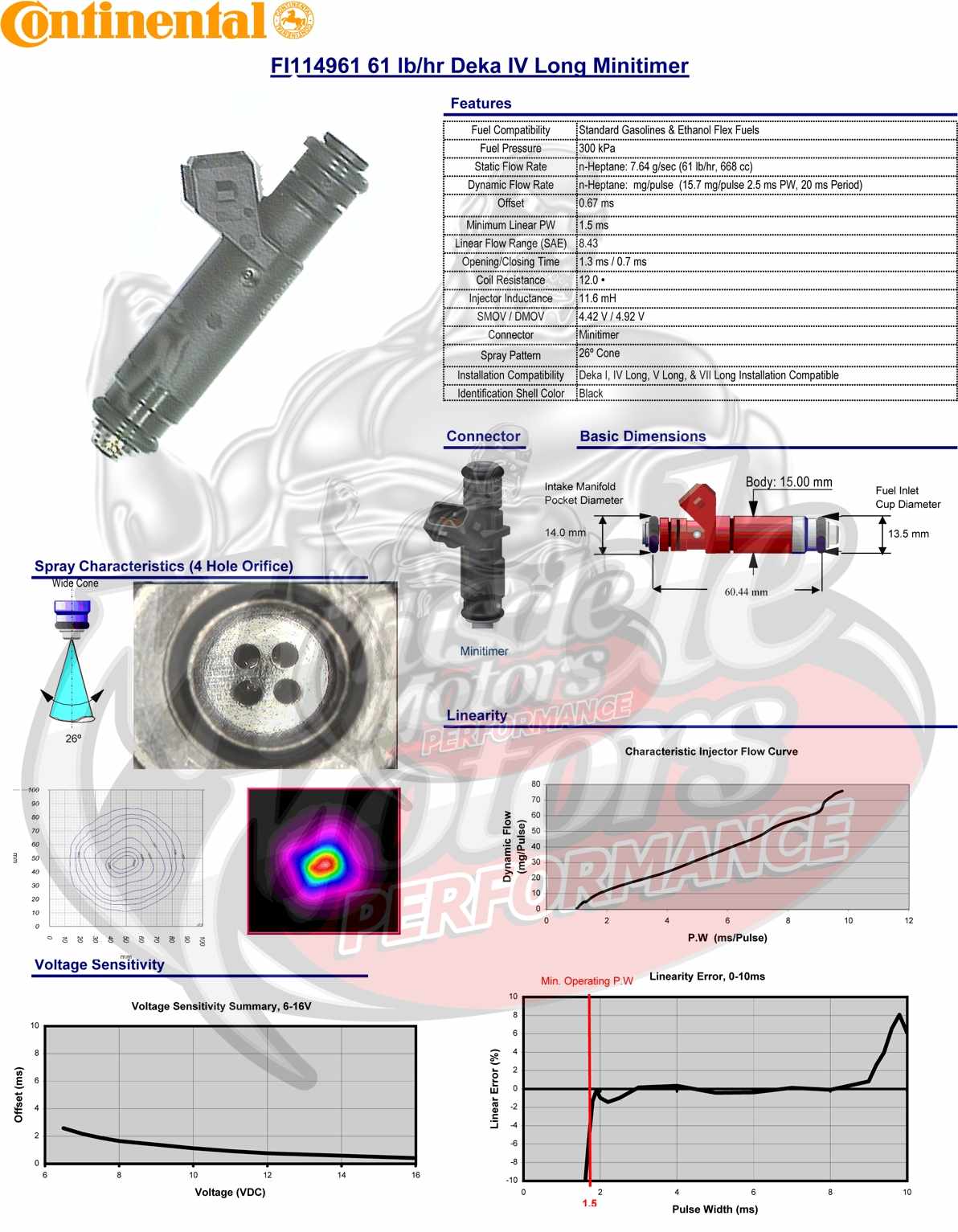

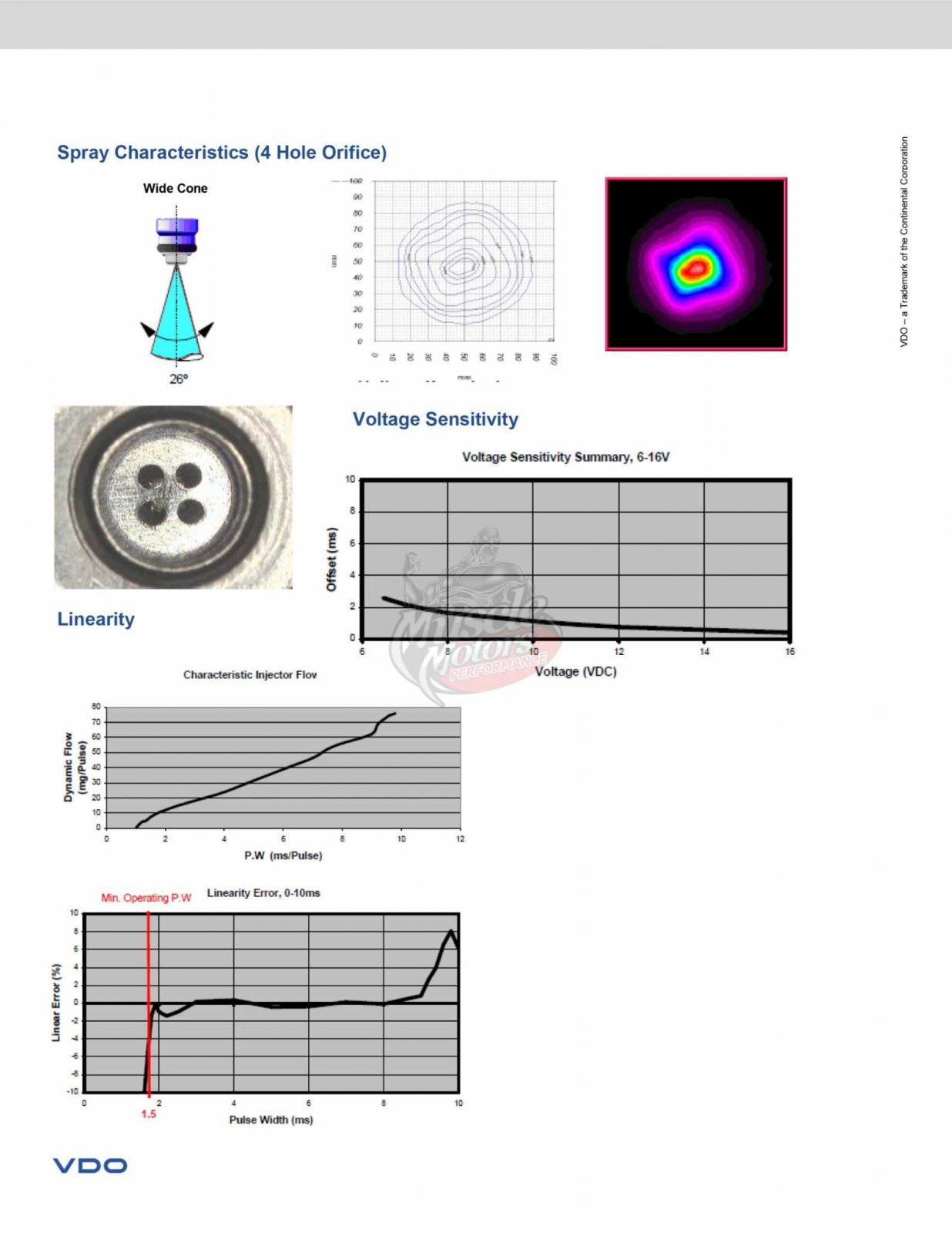

Question regarding the Injector Tuning. I have the ZZP Siemens deka 60lbs injectors. What I found on HP Tuners forum, is that with an injector usually a set of parameters come, which can be copy and paste into HP Tuners. I can not find this information for the injectors I have. The only thing I found are those 2 pictures below. Question 1: Does anyone have the factory data for the Siemens deka 60lbs injector?

Question 2: in the picture 1 it says Minimum Linear PW 1.5ms. In Hp Tuners, I have 0.094 ms for the 43lbs injector. This value should be 1.5ms according to the picture. That is factor 15 higher. It seems to me that this probaly should be 0.15ms. Which would indicate an error in the HP Tuner software. Can someone confirm that?

Question 2: in the picture 1 it says Minimum Linear PW 1.5ms. In Hp Tuners, I have 0.094 ms for the 43lbs injector. This value should be 1.5ms according to the picture. That is factor 15 higher. It seems to me that this probaly should be 0.15ms. Which would indicate an error in the HP Tuner software. Can someone confirm that?

It's under the mathHow are you getting injector duty cycle? I’ve only been able to find avg pulse width bank 1.

I don't think so. I think the graph is the actual duty cycle. With the old injectors I was at 125% but only when I was at high rpm and high boost. It was short enough that my wideband sensor never picked up a lean situation.Neat.

So your graph numbers are half values of duty cycle? 31.8 in the graph equals 63.6% duty cycle?

If so...I need to lay off the boost until I get different injectors.

How would I do that?You need to confirm the injector math is correct for a 4 cylinder, unless HPT labeled a for a 4 cylinder. Since it fires 2x more than an 8 cylinder per revolution the duty cycle is double for a 4 cylinder for the same pulse width.

I have limited doubt that the math is wrong. The old LSJs came with too small injectors. I had the 43lbs and maxed them out. Just eyeballing, the reading should be correct.

I think that works only IF the 4 cyl is the same displacement as the 8 cyl. Easy mistake.Not sure what I was thinking, but number of Cylinders does not figure into the calculation. Never mind.