Time for your yearly update

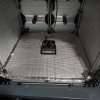

Lol... Well, I did order the upgraded DF Goblin shifter last month. Work has been busy and stressful this past year. I am also still crawling out of this @#@&%^$&*@% 3D printing college PhD level self-taught rabbit hole, without regretting the opportunity costs I may have wasted elsewhere, lol. I am fluent in 2 versions of gcode; about to learn the third. This printer I have built and mostly designed is great, but not perfect. I am convinced that it is due to firmware limitations and lack of specific developer interest per my current application and standards. I am halfway through printer build number 2, which will be running on new Linux based firmware and using a much better amount of processing power, speed, and resonance compensation which is more tailored to the type of machines I am building. The hardware on this one is all Chinese-based, but of surprisingly good quality. If this printer delivers, I will build the next one just like it, retrofit the first one, and be done. Fingers crossed...

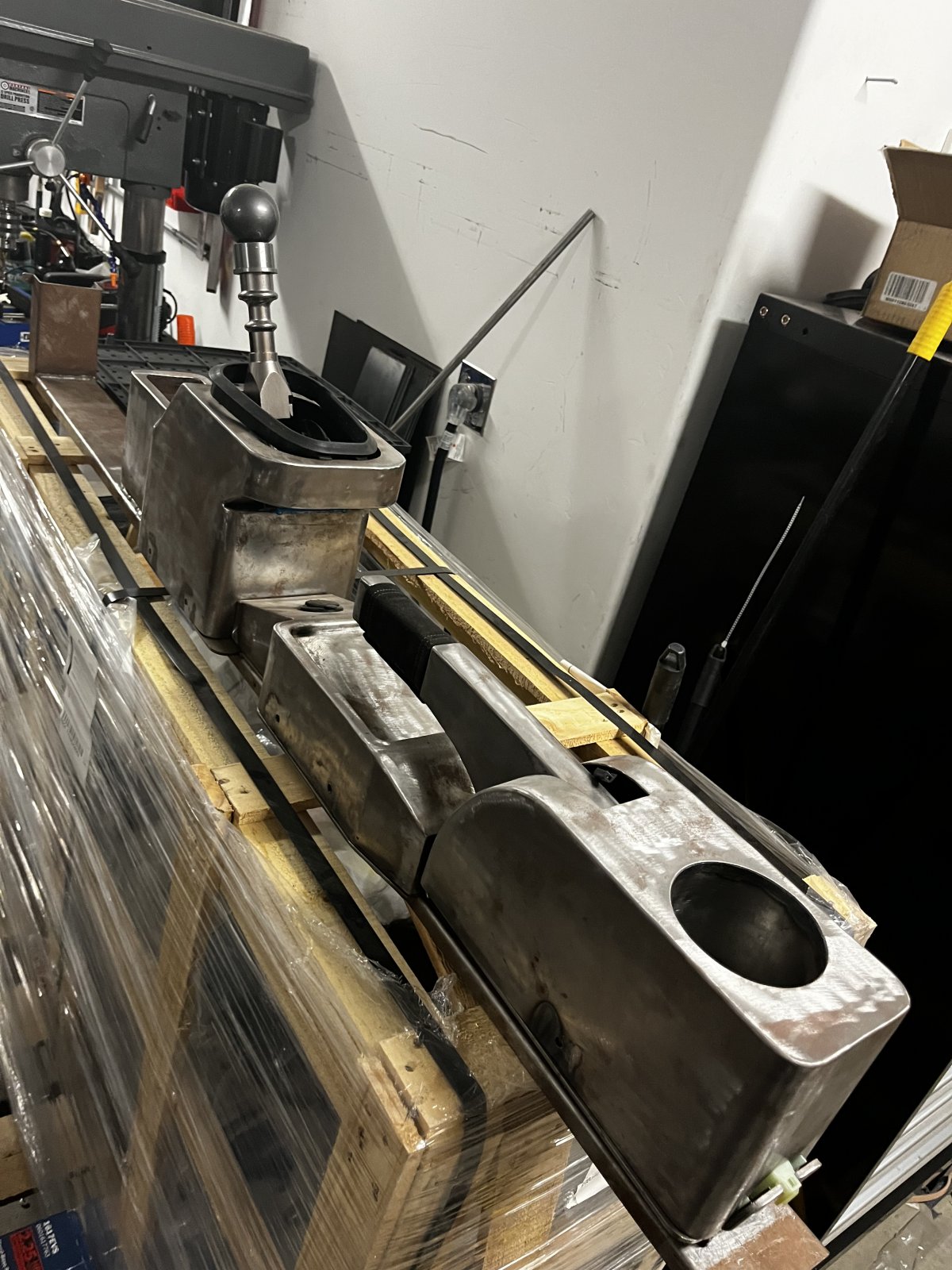

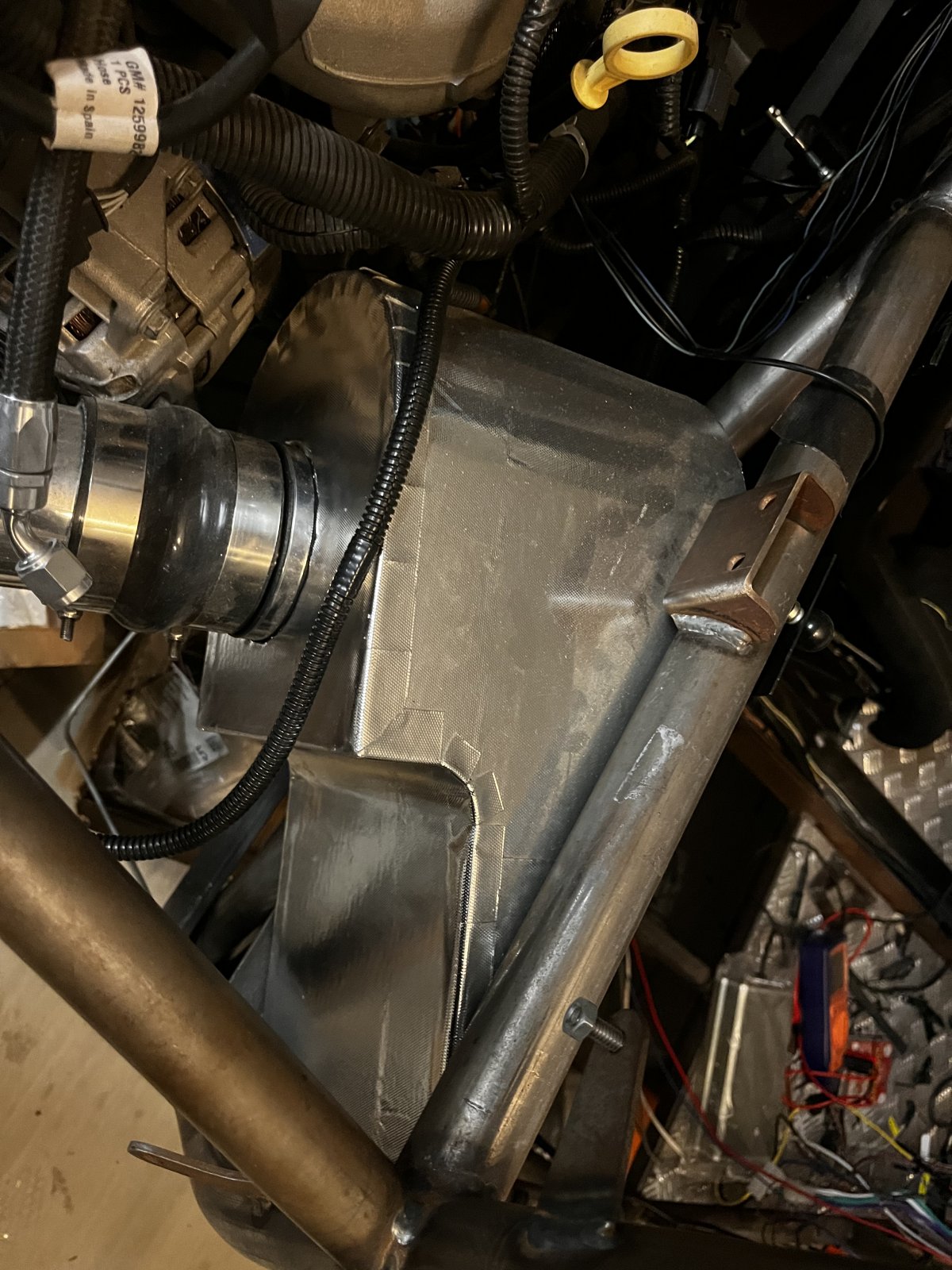

First up for the Goblin will still be a center console dimensional laser scan, followed by a 3 piece center console design (cupholders, charging port (perhaps a wireless charging pad), console storage box, and E-brake housing. I will also design a 3rd brake light, complete with integrated dome lamps, rear view camera and GPS antenna mount. I also want to redo my enclosed airbox design.

Trust me... I like 3D printing... But I like metal fabrication and building cars much better. To have the ability to efficiently laser scan, CAD design, 3D print, and fabricate metal will be even more fun. My goal is to get the printer **** figured out by the end of this summer and be back on my car project by fall.

I figured I'll start posting again when I get back to my build... Thanks for keeping me in mind.