neodied

Well-Known Member

Since I didn't save the parking brake cables and tubes from my donor, I chose to use the Amazon kit mentioned in this thread (credit to @Hellproof) :

330-9371 Parking Brake Cable Kit Fit for Wilwood 110" Long Cables with a 97" Long Sheath, Universal Emergency Brake Cable Repair Kit

https://a.co/d/jiJrO0C

There were a few hurdles to clear and I figured I'd write it up in case anyone else has to do the same. This only applies if you still have the Cobalt parking brake handle and the small cable with the adjuster nut that goes in the handle.

Additional parts needed:

4x M10 washer

2x M10 nylok nut

I started at the caliper. Remove the inner cable from the sheath, and remove the nylok nut that comes with the cables.

I found that the nuts that came with the kit were terrible quality, gouging the threads on the sheath. So I got new ones and ran over the damaged threads with an M10x1.25 thread cutting die to smooth it out.

Assemble at the caliper as seen in the picture. Getting a wrench or socket on the nut is impossible even with the wheel off, so I just jammed a large screwdriver against the nut to hold it while turning the sheath with an adjustable wrench.

Then put the inner cable back in.

Fish the cables between the tunnel and the rear firewall (I went over the front of the subframe and over the brake line) with plenty of extra length to work with.

Remove the parking brake handle assembly.

Remove the aluminum barrel-looking nut assembly from the kit's L bracket and put them in the parking brake handle assembly like the picture below.

The tube-ish spacers on the left go over the sheath inside the barrel nut, but don't try to hold them in without the cable or you might drop them in the open end of the tunnel like me and spend an hour trying to fish them out.....

Then remove the Cobalt's tension balancer bracket (red X in photo) from the small handle cable (I used a Dremel cutoff wheel).

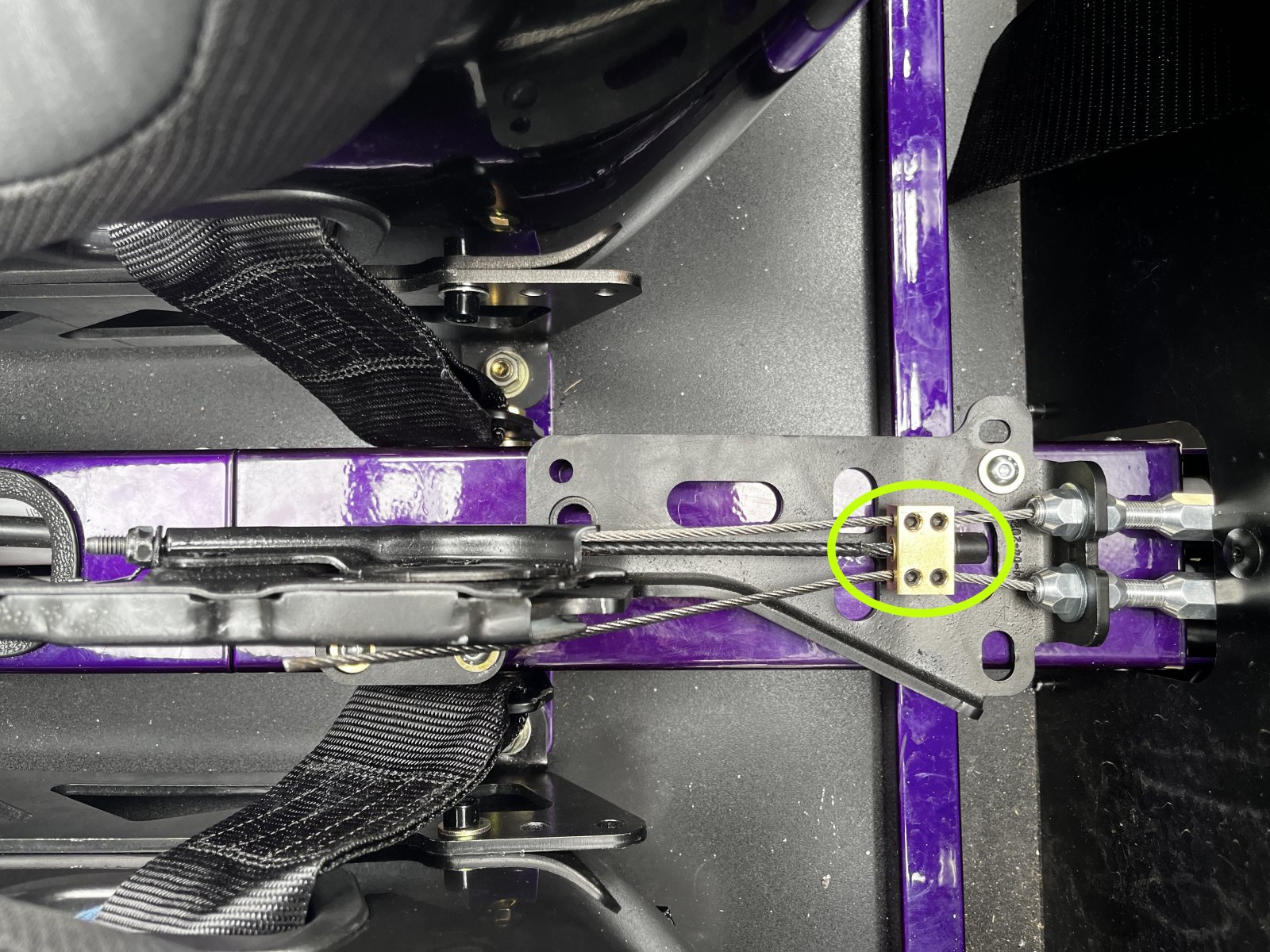

Use a 5/16" drill bit to drill enlarge the threaded center hole of the brass block with 4 set screws (circled in yellow below).

This is where the handle cable will go.

Then put the sheath+cables through the barrel nuts and the inner cables through the brass block, tightening set screws to hold the cables in place temporarily.

Pull the handle cable through the brass block and into the handle, replacing its adjuster nut.

Tighten the aluminum barrel nut assembly. I moved it rearward as much as possible to leave lots of space forward of the bracket for adjustment.

Re-mount the handle assembly on the tunnel cap.

Loosen the brass block set screws and pull all the slack out of the cables.

Tighten the set screws, give the handle a yank, then loosen the set screws and re-tighten the cables.

There is a lot of extra length between the caliper and firewall for this length of cable.

If I were to re-order these, I would try to find some that had a sheath that was 2 or 3 feet shorter.

Barring some reason to redo this with shorter cables, I'm just going to route the excess in a wide arc under the subframe.

330-9371 Parking Brake Cable Kit Fit for Wilwood 110" Long Cables with a 97" Long Sheath, Universal Emergency Brake Cable Repair Kit

https://a.co/d/jiJrO0C

There were a few hurdles to clear and I figured I'd write it up in case anyone else has to do the same. This only applies if you still have the Cobalt parking brake handle and the small cable with the adjuster nut that goes in the handle.

Additional parts needed:

4x M10 washer

2x M10 nylok nut

I started at the caliper. Remove the inner cable from the sheath, and remove the nylok nut that comes with the cables.

I found that the nuts that came with the kit were terrible quality, gouging the threads on the sheath. So I got new ones and ran over the damaged threads with an M10x1.25 thread cutting die to smooth it out.

Assemble at the caliper as seen in the picture. Getting a wrench or socket on the nut is impossible even with the wheel off, so I just jammed a large screwdriver against the nut to hold it while turning the sheath with an adjustable wrench.

Then put the inner cable back in.

Fish the cables between the tunnel and the rear firewall (I went over the front of the subframe and over the brake line) with plenty of extra length to work with.

Remove the parking brake handle assembly.

Remove the aluminum barrel-looking nut assembly from the kit's L bracket and put them in the parking brake handle assembly like the picture below.

The tube-ish spacers on the left go over the sheath inside the barrel nut, but don't try to hold them in without the cable or you might drop them in the open end of the tunnel like me and spend an hour trying to fish them out.....

Then remove the Cobalt's tension balancer bracket (red X in photo) from the small handle cable (I used a Dremel cutoff wheel).

Use a 5/16" drill bit to drill enlarge the threaded center hole of the brass block with 4 set screws (circled in yellow below).

This is where the handle cable will go.

Then put the sheath+cables through the barrel nuts and the inner cables through the brass block, tightening set screws to hold the cables in place temporarily.

Pull the handle cable through the brass block and into the handle, replacing its adjuster nut.

Tighten the aluminum barrel nut assembly. I moved it rearward as much as possible to leave lots of space forward of the bracket for adjustment.

Re-mount the handle assembly on the tunnel cap.

Loosen the brass block set screws and pull all the slack out of the cables.

Tighten the set screws, give the handle a yank, then loosen the set screws and re-tighten the cables.

There is a lot of extra length between the caliper and firewall for this length of cable.

If I were to re-order these, I would try to find some that had a sheath that was 2 or 3 feet shorter.

Barring some reason to redo this with shorter cables, I'm just going to route the excess in a wide arc under the subframe.