Rauq

Goblin Guru

I repolled parameters and still don't see anything that I think could or should be SCIP.

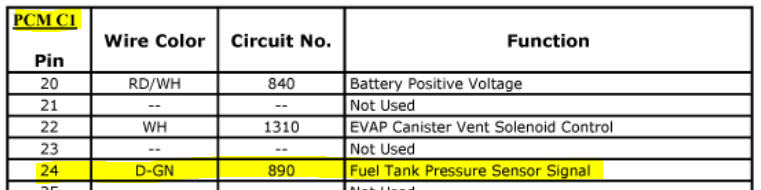

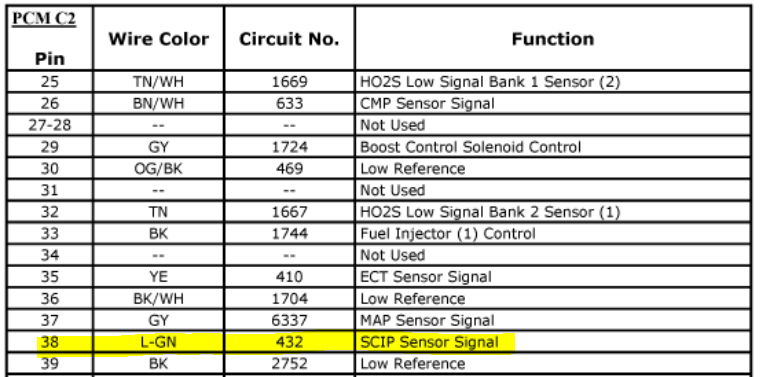

What I'm thinking of doing now is pulling the PCM pin for SCIP input and sticking it in the Fuel Tank Pressure slot. I can log that PID (it comes up as 0v all the time) and will map it for SCIP in HP Tuners. As far as I can tell that slot on C1 should be empty on an '06 LSJ. I don't think it'll cause a CEL or other symptom seeing erratic readings there, and if it did, I would imagine it would only cause an EVAP related CEL which is already squared away. Diagrams are given below, mostly for my own future reference.

My major interest in logging SCIP is that I should be able to tell how much, if any, I'm compounding boost with the twincharged setup. I expect it to compound under 15psi which is where the supercharger bypass should be fully open. The SCIP should basically be turbo-only boost and the MAP is post-supercharger boost. Unfortunately as far as I can tell the AEM Tru Boost controller doesn't have an analog output for boost level, so this is my next most creative solution.

What I'm thinking of doing now is pulling the PCM pin for SCIP input and sticking it in the Fuel Tank Pressure slot. I can log that PID (it comes up as 0v all the time) and will map it for SCIP in HP Tuners. As far as I can tell that slot on C1 should be empty on an '06 LSJ. I don't think it'll cause a CEL or other symptom seeing erratic readings there, and if it did, I would imagine it would only cause an EVAP related CEL which is already squared away. Diagrams are given below, mostly for my own future reference.

My major interest in logging SCIP is that I should be able to tell how much, if any, I'm compounding boost with the twincharged setup. I expect it to compound under 15psi which is where the supercharger bypass should be fully open. The SCIP should basically be turbo-only boost and the MAP is post-supercharger boost. Unfortunately as far as I can tell the AEM Tru Boost controller doesn't have an analog output for boost level, so this is my next most creative solution.