Brian74

Goblin Guru

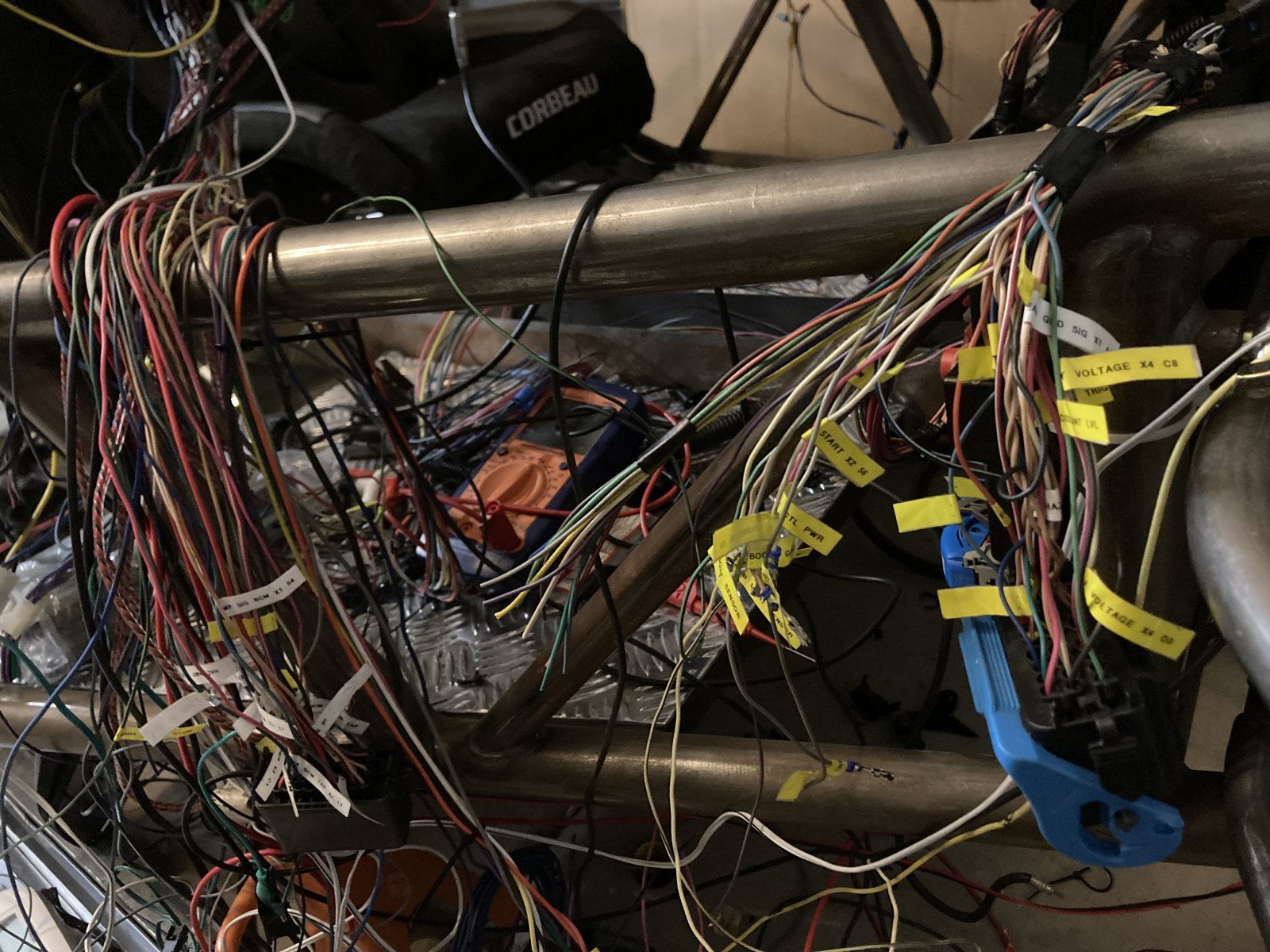

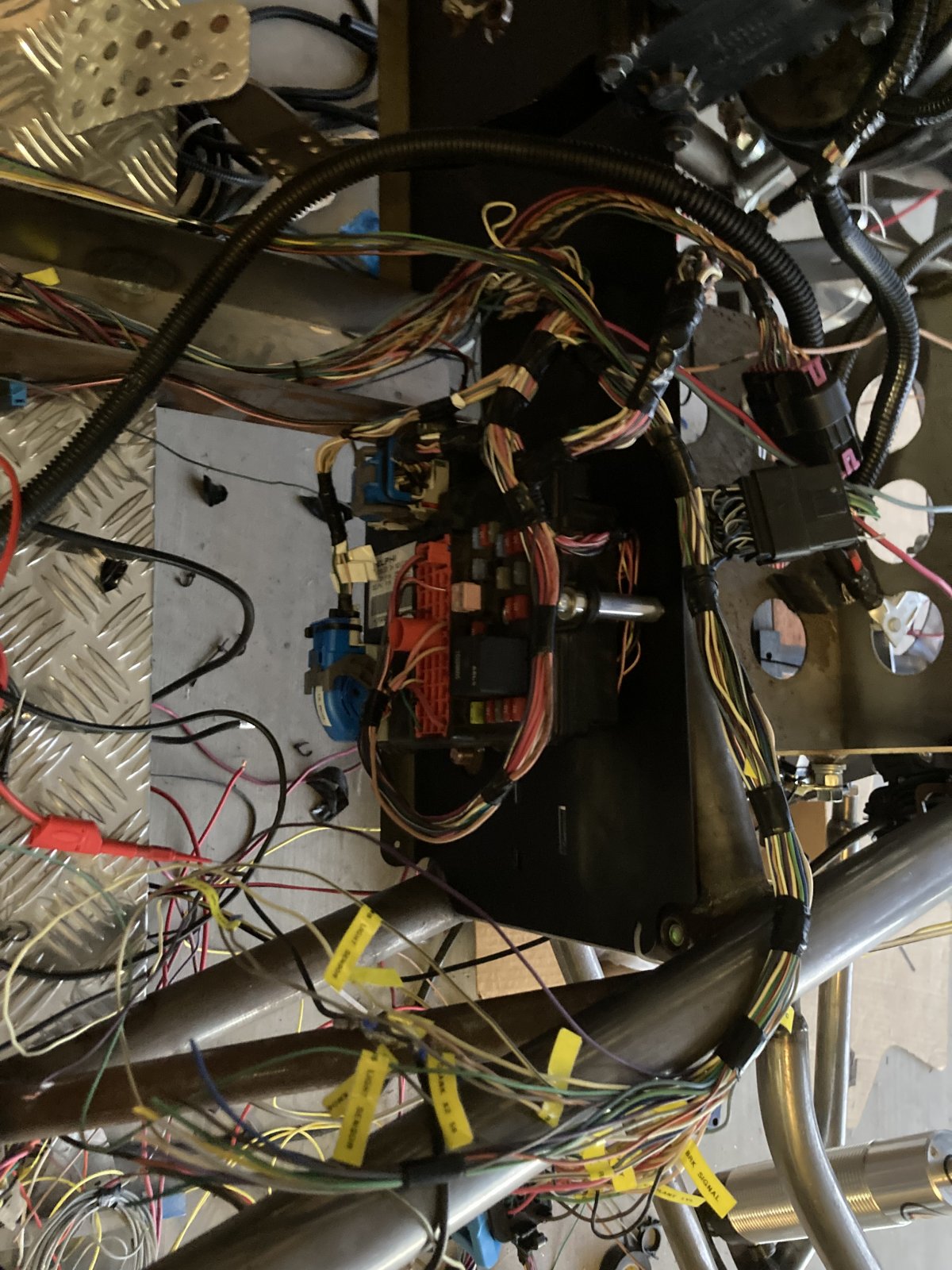

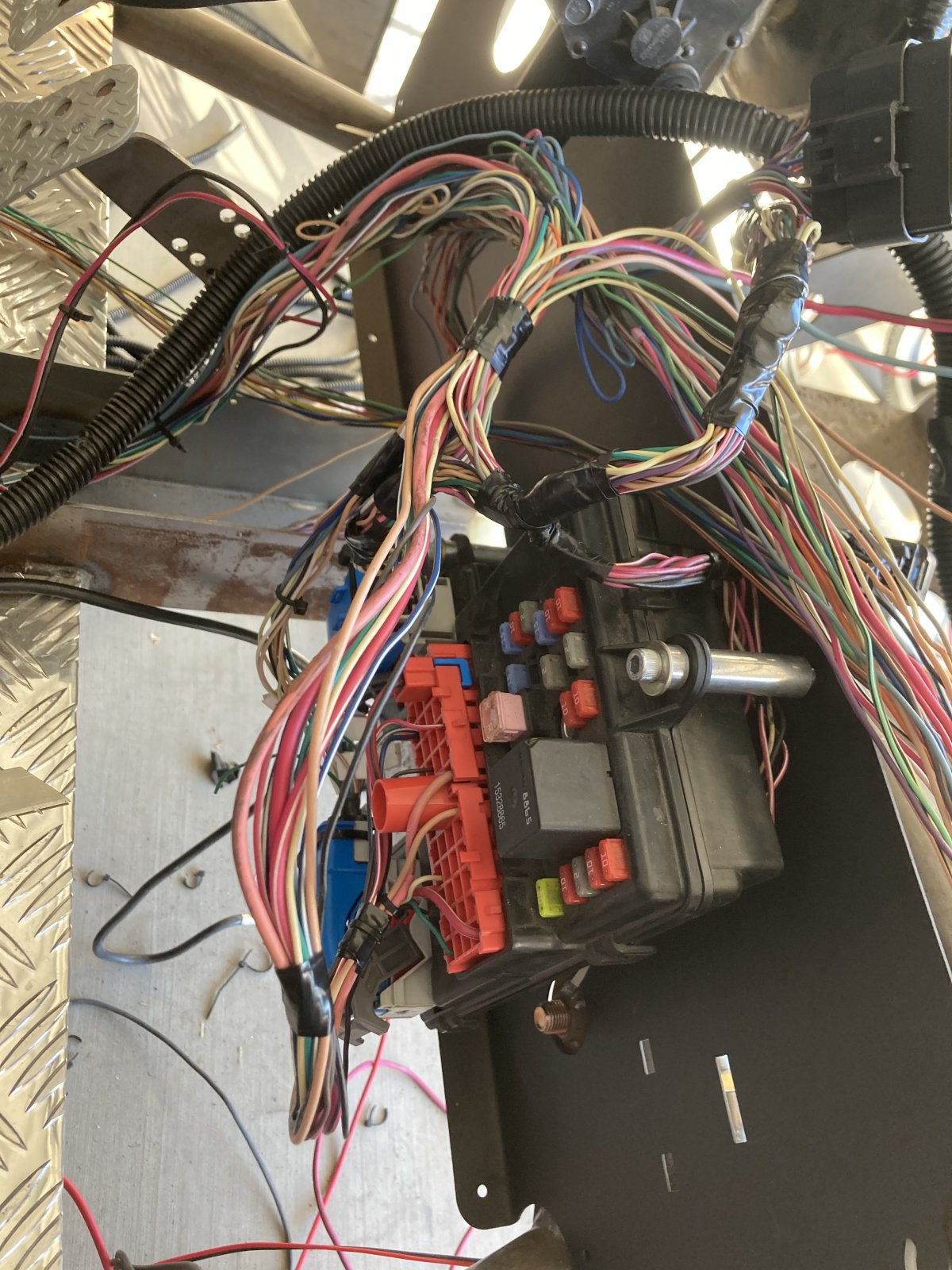

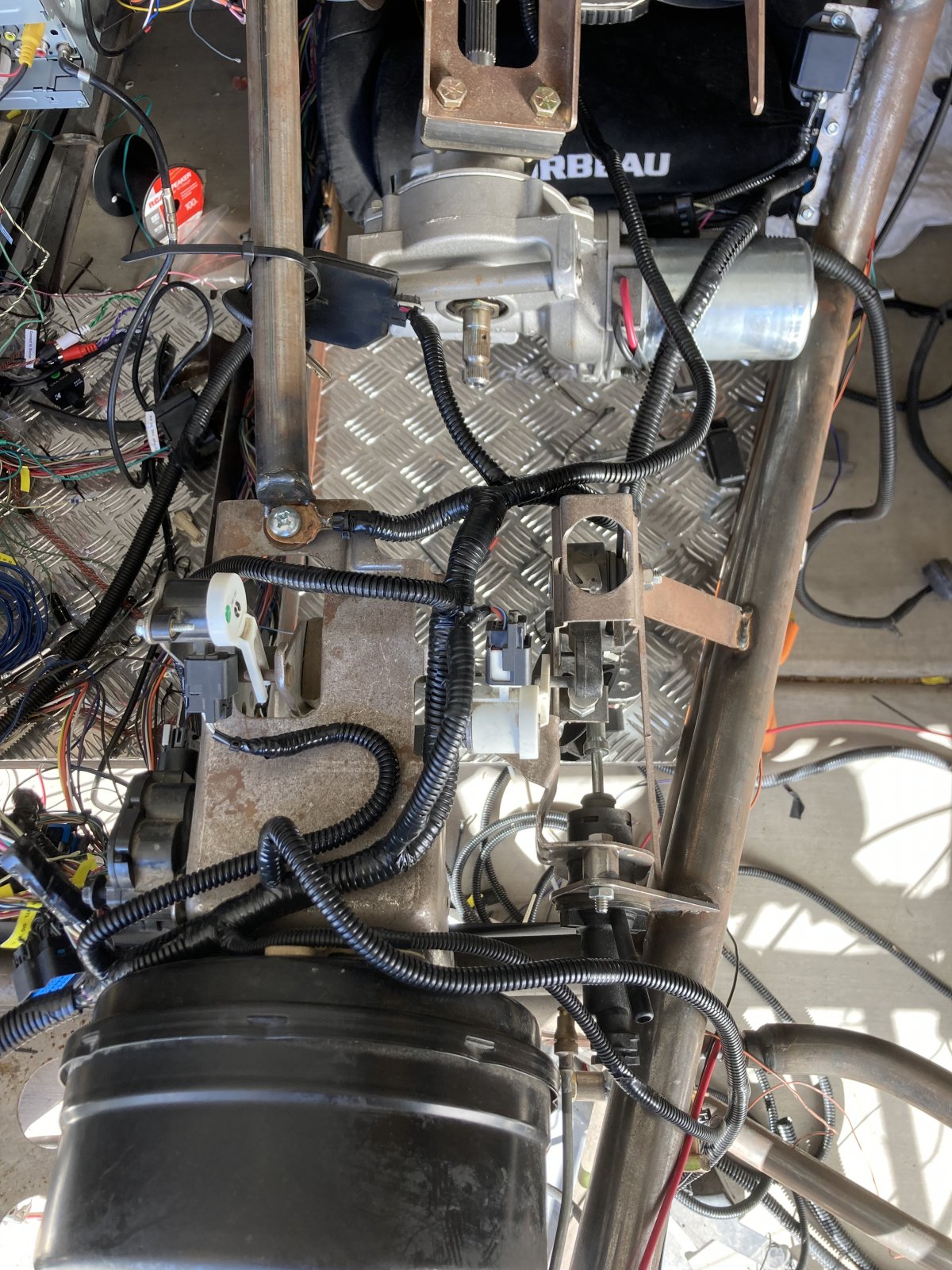

Got back on the build this last weekend. Re-attacked the wiring harness. Firewall fwd portion is wrapped and loomed. Now I’ve got 33 wires to attach to the dash from the body harness, and 7 spare wires that I added into the harness in case I need to add anything later.

I still need to wire in my fog lights and the fog light actuators and relays. I’ve also got 8 LED courtesy lights I still need to build a junction harness for and wire in.

I had an extra Cobalt harness that I had pulled from a jy for around $5. I ran it across the garage floor, stripped the loom, and came out with around 300’ of nice quality wire. For the price of quality wire these days, the hour it took was worth it. I used some of it to add in spare wires for my existing harness.

Wiring the dash was super easy because I already had a plan. Kinda wishing I would have just designed my body harness from scratch to begin with as well. Its challenging and costly making harness run decisions on the fly.

I still need to wire in my fog lights and the fog light actuators and relays. I’ve also got 8 LED courtesy lights I still need to build a junction harness for and wire in.

I had an extra Cobalt harness that I had pulled from a jy for around $5. I ran it across the garage floor, stripped the loom, and came out with around 300’ of nice quality wire. For the price of quality wire these days, the hour it took was worth it. I used some of it to add in spare wires for my existing harness.

Wiring the dash was super easy because I already had a plan. Kinda wishing I would have just designed my body harness from scratch to begin with as well. Its challenging and costly making harness run decisions on the fly.