The time has finally come for me to address the question of exhaust. Because I am in Georgia, I do not believe I will be able to obtain registration without emissions compliant exhaust in place. With this said, I'm trying to figure out how I can get an exhaust built out without having to trailer the car to an exhaust shop. I know a few have done this. What is a good way to go about this? I have never designed an exhaust system before but definitely would like to give it a shot if its not too entirely difficult

Exhaust Options

- Thread starter finazzoty

- Start date

Joebob

Goblin Guru

It is not too dificult to do.

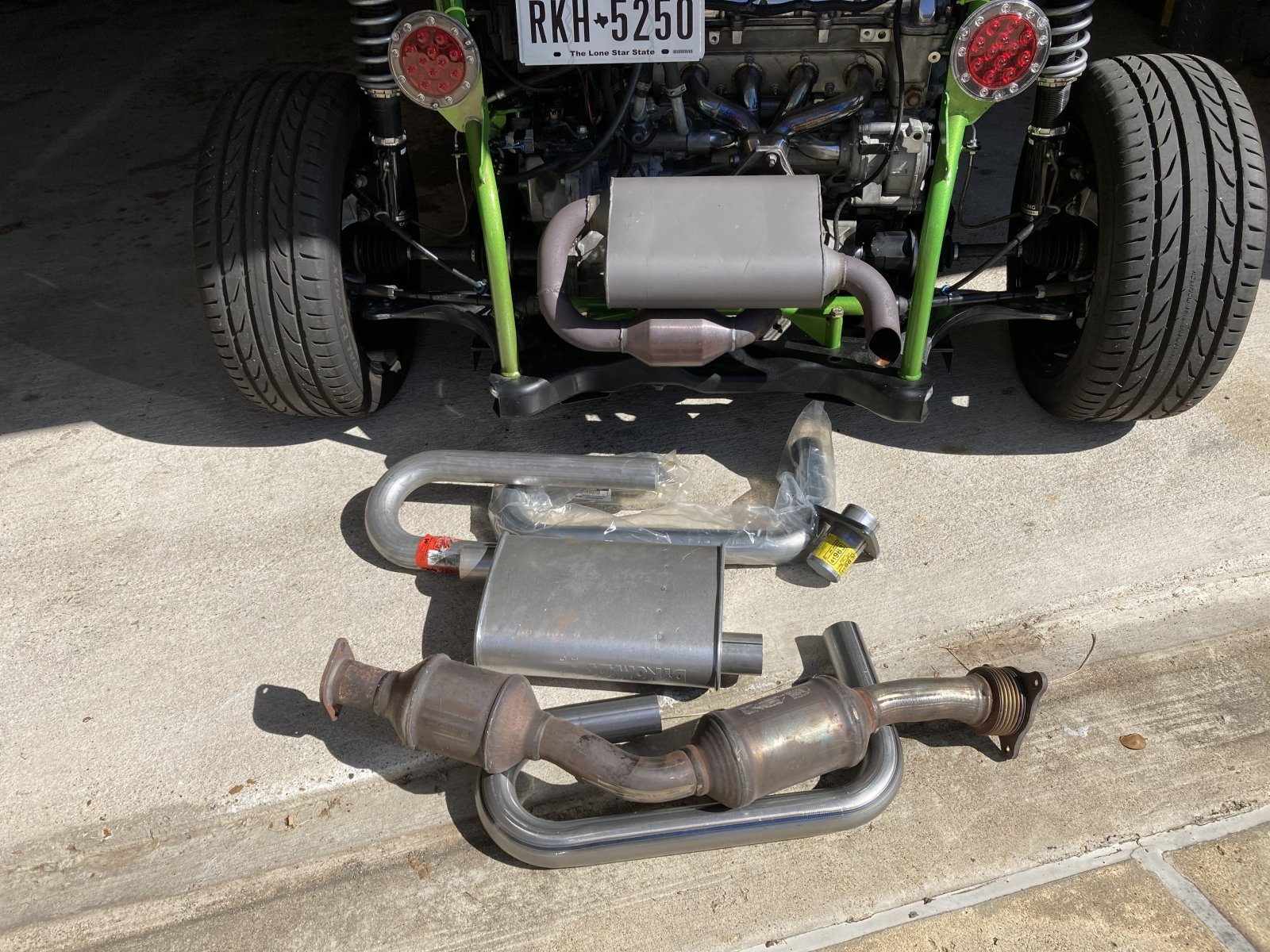

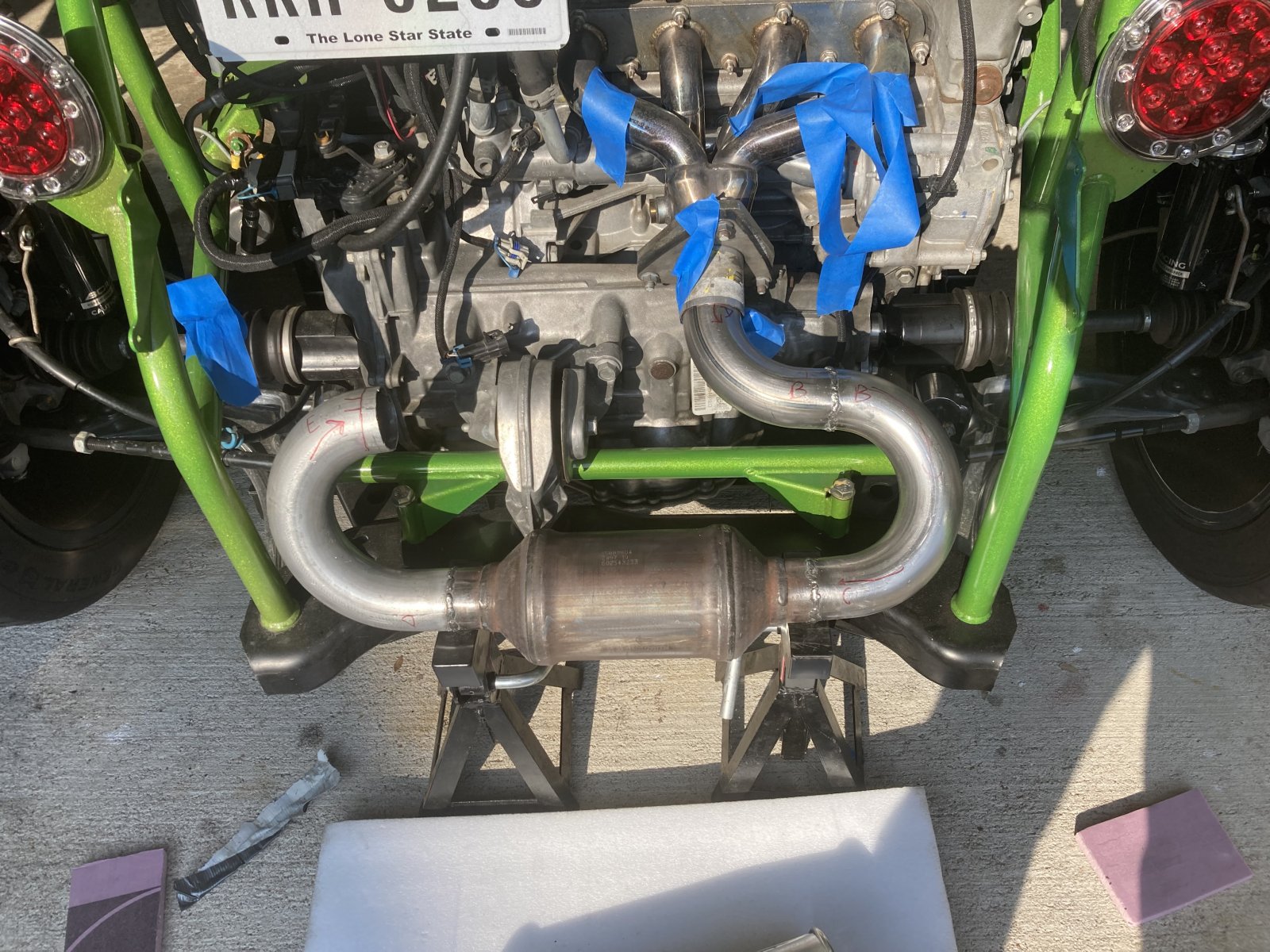

I was limited to Flux core which means non stainless steel was my only choice. I used the donor cat and a dynomax Superturbo muffler and matched the donor 2.25" pipe. I got some various lengths and bends to design the system. I got the 16 gauge pipe as I was afraid of burning through and did in a few spots but it makes the exhaust pretty heavy. I also didn't want to splice in a short straight section in the 180 degree bends and 2 more welds so the exhaust sits farther back from the engine which adds more cantilever forces. I did weld up a support arm that has a cusioed bolting to the subframe to offset this.

Hardest part os squaring everything up to have no gaps to try to weld closed. Oh and if you get aluminuzed steel, try to grind off the aluminum as is seems to weld better and splatter less if you do.

Just be prepared for a near infinite amount of test fitting.

I was limited to Flux core which means non stainless steel was my only choice. I used the donor cat and a dynomax Superturbo muffler and matched the donor 2.25" pipe. I got some various lengths and bends to design the system. I got the 16 gauge pipe as I was afraid of burning through and did in a few spots but it makes the exhaust pretty heavy. I also didn't want to splice in a short straight section in the 180 degree bends and 2 more welds so the exhaust sits farther back from the engine which adds more cantilever forces. I did weld up a support arm that has a cusioed bolting to the subframe to offset this.

Hardest part os squaring everything up to have no gaps to try to weld closed. Oh and if you get aluminuzed steel, try to grind off the aluminum as is seems to weld better and splatter less if you do.

Just be prepared for a near infinite amount of test fitting.

Ross

Goblin Guru

Flux core is just a way to displace the oxygen in the air. The flux vaporizes when welding, making smoke, with no oxygen. Stick welding has flux on the outside of the welding rod. The alternative way to displace the air is to have a bottle of gas hooked up to your welder.

Since they sell it, you can weld it that way.

Since they sell it, you can weld it that way.

escapepilot

Goblin Guru

There are also health issues to take into account welding stainless. Just google it to be aware before you start. You could also use plain non-aluminized steel tubing for your mock up then have a shop build a final one out of stainless.

I REALLY appreciate you mentioning this as I was not at all aware. I’ve done some reading now and some recommendations are saying a PAPR is needed?? I definitely do not want to inhale any chromium, but I also don’t particularly love the idea of spending $1000+ on a PAPR. I know safety is nothing to play with, but think I’d be alright if I did it outside with a regular respirator and a box fan blowing a light breeze across my work area?There are also health issues to take into account welding stainless. Just google it to be aware before you start. You could also use plain non-aluminized steel tubing for your mock up then have a shop build a final one out of stainless.

Welding Disposable Respirators - Grainger Industrial Supply plus welding in a well ventilated area

GoblinGuyZ

Well-Known Member

This is what I did for mine, made this up quickly for someone else in the forum who asked...

Dsteinhorst

Well-Known Member

These guys might make you something. I would expect it to be on the pricier end, but it seems like a premium product. I cannot speak for actual quality, and I am not endorsing; just sharing an option.

escapepilot

Goblin Guru

I have two complaints with standard exhaust - it is very loud and it doesn't look good. It's loud enough that mashing the go pedal announces to the whole world what you are doing and sometimes stealth mode is preferred. I have seen more attractive options, but have not seen a definitive solution to the noise level issue.

Desert Sasqwatch

Goblin Guru

Maybe this is more the style you need? LOL!

escapepilot

Goblin Guru

Problem SOLVED!Maybe this is more the style you need? LOL!

Dsteinhorst

Well-Known Member

Ditto, I'd pay a decent amount of money for a nice quiet exhaust!I have not seen a definitive solution to the noise level issue.

Metal Mech

Well-Known Member

Love your exhaust. I’d love to have one just like that but I don’t have the skill to make one.This is what I did for mine, made this up quickly for someone else in the forum who asked...