BAR-AIR

Well-Known Member

Well kind of a crappy day working on the brake system. What should have been a simple day of tightening all the finger tight connections and power bleeding the system turned into most likely pulling the system out to replace the lines and tees.

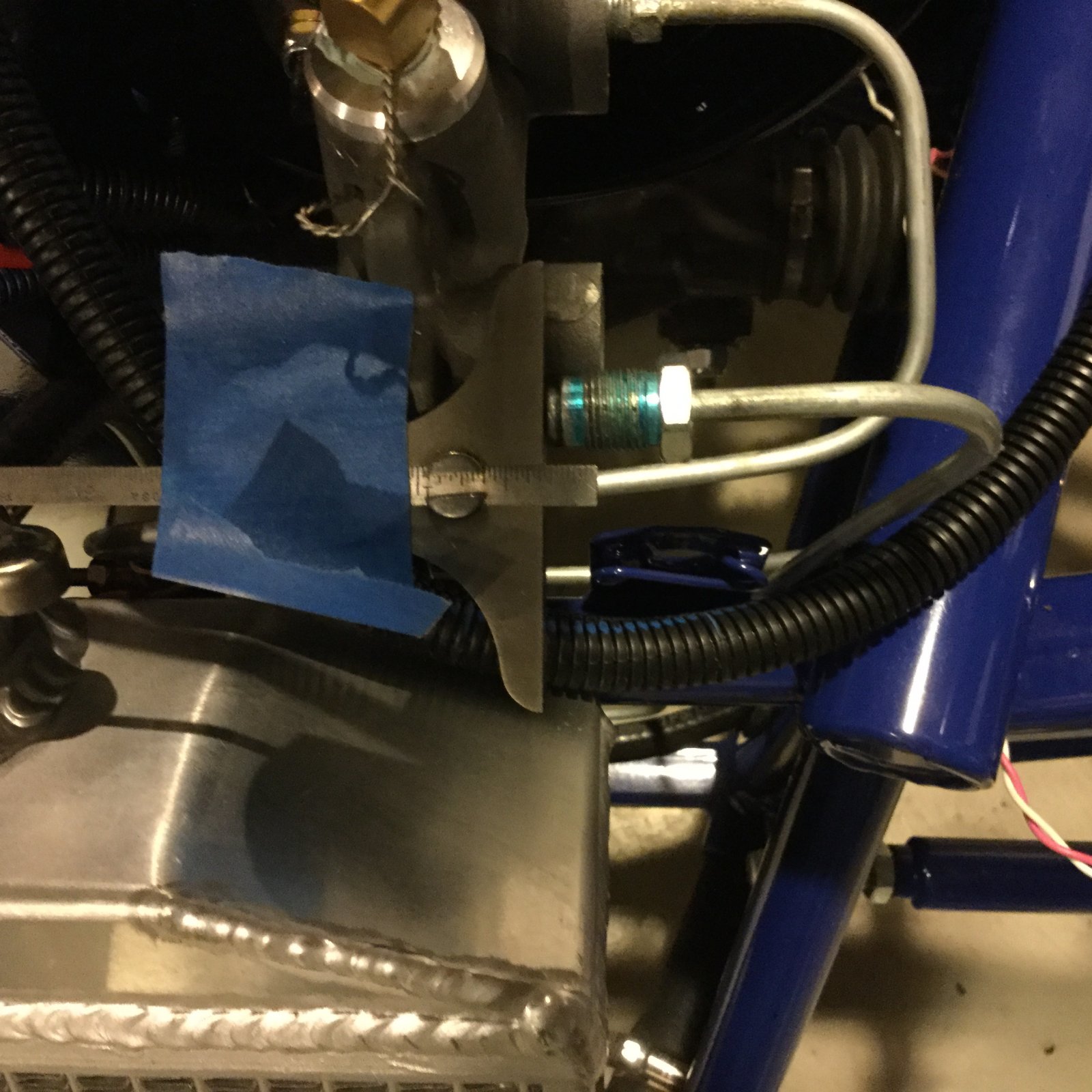

So here are somethings to look out for... photo below is a 2008 master cylinder and the supplied brake line. The connector is a M12x1, the brake line has an inverted (double flare). Problem is the brake line connector is a bubble flare connector not the inverted flare connector simply will NOT work you only have about 9/32" depth in the master cylinder you catch a thread to a thread in a half. The connector you will need is a BQ9180 Brakequip. So OK I just got unlucky and the wrong connector was used. So I find the correct connector (not available at auto parts stores) cut off the flared end and reflare with correct connector.

Fill brake reservoir life should be good again.

NOPE.... Main brake line the one I just replaced the connector on the other end is pissing fluid like it is not even connected go to tighten it is tight but line is still loose. This end basically has a inverted flare connector on a bubble flare line (tees have all bubble flare ends). So splice in a bubble flare line into the long line. That line was not long enough to just cut and reflare with correct connector. Re connect add only a little fluid because I'm already swimming in fluid, now the two other lines begin leaking also notice the front tee is also leaking slightly from at least two of the connections.

So after talking to Lonny and a reexamination of the lines and the tees in a perfect world if the tees are completely threaded all the way to the bottom where the thread would meet the angle for the bubble flare (they are not). The supplied brake lines with the bubble flares and the completely threaded connectors will work. If not they will bottom out the threads before seating the lines and will leak (ALOT!!!)

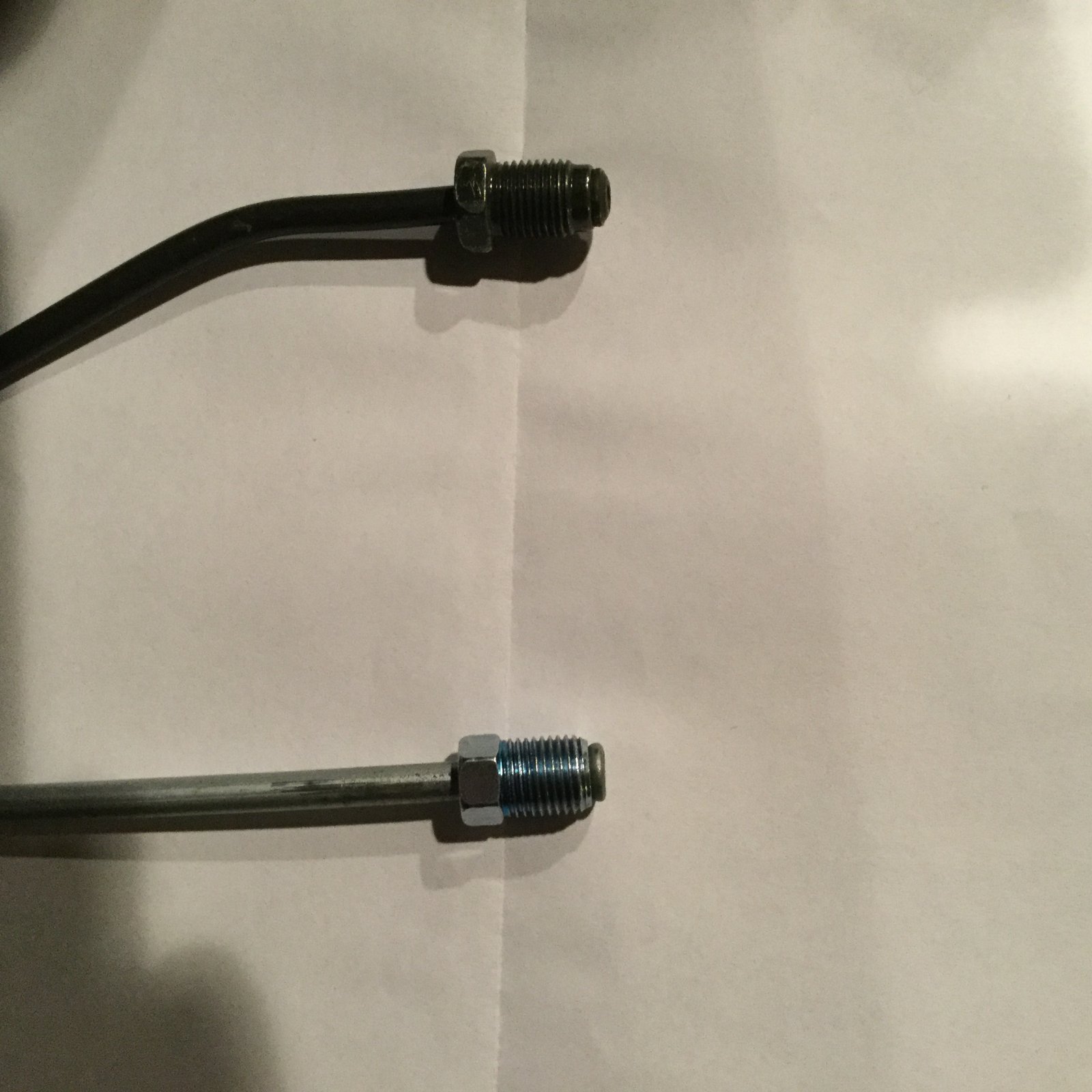

Below is a photo of the supplied line the bottom one you can see it is threaded to the flare (that same connector was used on both inverted and bubble flares). The upper connector (not the right size just what I had for photo purposes) the connector has a step back for the threads so that even if the tees are not completely threaded the lines would still be seated.

After talking with the guys at DFKITCAR just snug the lines as tight as possible to see if you can get them to seat none of the supplied lines at the tees seated (even using tube wrenches stripped two connectors) and they still leak. The only one that did not leak was the replaced bubble flare connector with the step back.

So check your lines and your tees. I have a finished car for all practical purposes and am going to have to pull some of if apart just to replace lines. And the kicker, is there is a couple of week lead time to get me new lines...

So basically a crappy day in kit car world.

So here are somethings to look out for... photo below is a 2008 master cylinder and the supplied brake line. The connector is a M12x1, the brake line has an inverted (double flare). Problem is the brake line connector is a bubble flare connector not the inverted flare connector simply will NOT work you only have about 9/32" depth in the master cylinder you catch a thread to a thread in a half. The connector you will need is a BQ9180 Brakequip. So OK I just got unlucky and the wrong connector was used. So I find the correct connector (not available at auto parts stores) cut off the flared end and reflare with correct connector.

Fill brake reservoir life should be good again.

NOPE.... Main brake line the one I just replaced the connector on the other end is pissing fluid like it is not even connected go to tighten it is tight but line is still loose. This end basically has a inverted flare connector on a bubble flare line (tees have all bubble flare ends). So splice in a bubble flare line into the long line. That line was not long enough to just cut and reflare with correct connector. Re connect add only a little fluid because I'm already swimming in fluid, now the two other lines begin leaking also notice the front tee is also leaking slightly from at least two of the connections.

So after talking to Lonny and a reexamination of the lines and the tees in a perfect world if the tees are completely threaded all the way to the bottom where the thread would meet the angle for the bubble flare (they are not). The supplied brake lines with the bubble flares and the completely threaded connectors will work. If not they will bottom out the threads before seating the lines and will leak (ALOT!!!)

Below is a photo of the supplied line the bottom one you can see it is threaded to the flare (that same connector was used on both inverted and bubble flares). The upper connector (not the right size just what I had for photo purposes) the connector has a step back for the threads so that even if the tees are not completely threaded the lines would still be seated.

After talking with the guys at DFKITCAR just snug the lines as tight as possible to see if you can get them to seat none of the supplied lines at the tees seated (even using tube wrenches stripped two connectors) and they still leak. The only one that did not leak was the replaced bubble flare connector with the step back.

So check your lines and your tees. I have a finished car for all practical purposes and am going to have to pull some of if apart just to replace lines. And the kicker, is there is a couple of week lead time to get me new lines...

So basically a crappy day in kit car world.