ncgoblin

Goblin Guru

Hey all,

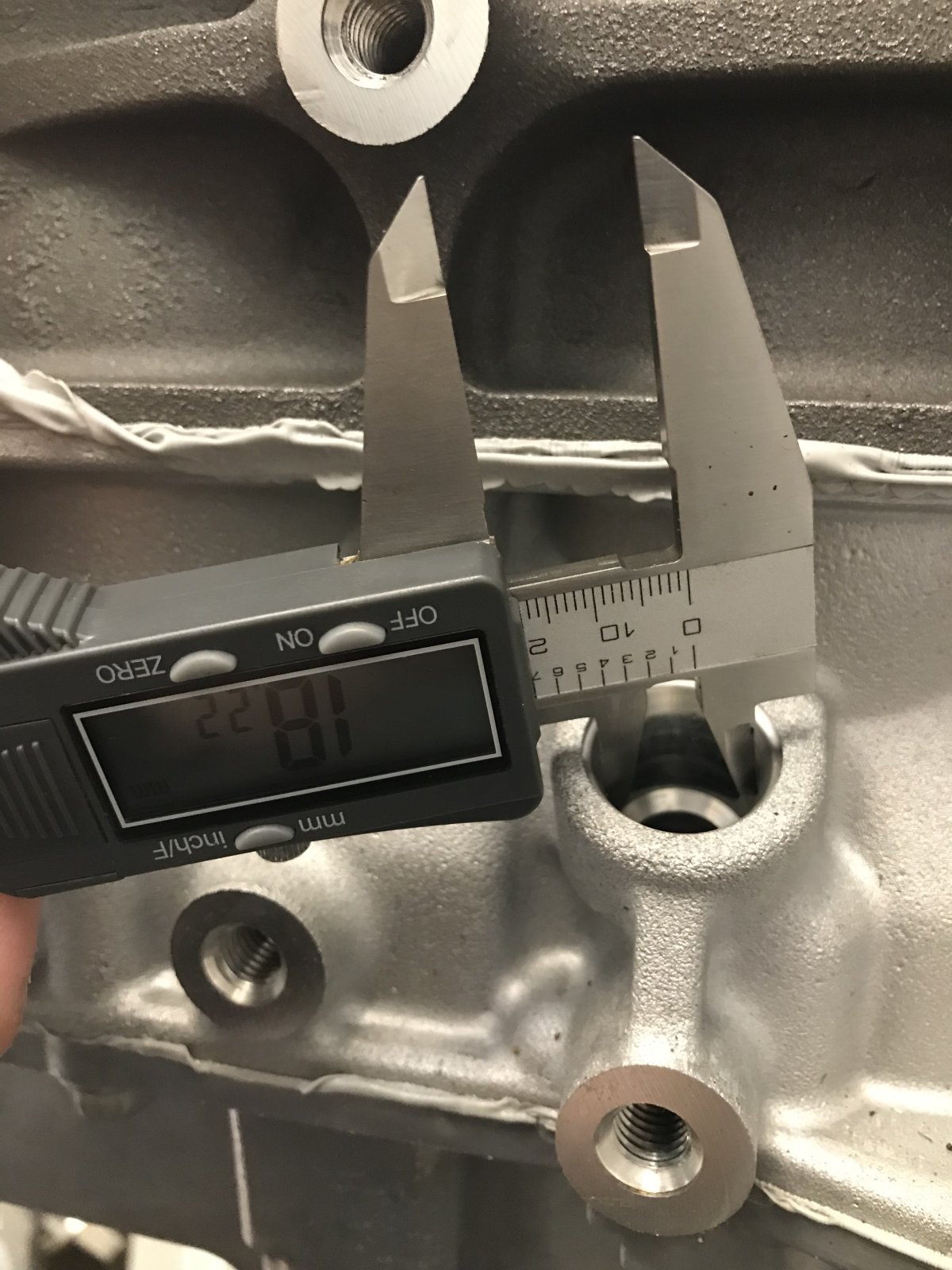

I am going to start my LDK / LSJ build soon as some of you know I had used engine issues and I have decided I’m just going to build it correct with a new block. I have to pull the main girdle and swap the crank reluctor wheel so I need to cap off this turbo oil feed since I’m going supercharged. The hole is a little over 18mm what do you all think? I have contemplated putting my oil pressure sender in that location. Funny thing is out of all things I have done threading bolt holes is not one. I will update this thread to include my build process.

l

I am going to start my LDK / LSJ build soon as some of you know I had used engine issues and I have decided I’m just going to build it correct with a new block. I have to pull the main girdle and swap the crank reluctor wheel so I need to cap off this turbo oil feed since I’m going supercharged. The hole is a little over 18mm what do you all think? I have contemplated putting my oil pressure sender in that location. Funny thing is out of all things I have done threading bolt holes is not one. I will update this thread to include my build process.

l