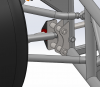

Had a good weekend. Managed to finish all of the fab work on the rear!

And it's completely bolt on.

Only time will tell on performance, but I'm really happy with the way it looks.

Up next, I need to finalize the mods on the front suspension. Unfortunately, it won't be bolt on, gonna have to poke some holes in the chassis.

And it's completely bolt on.

Only time will tell on performance, but I'm really happy with the way it looks.

Up next, I need to finalize the mods on the front suspension. Unfortunately, it won't be bolt on, gonna have to poke some holes in the chassis.