Quick disclaimer: I see lots of build logs here with picture after picture of pristine Goblins. This will not be one of those build logs.

TLDR: I could use some suggestions at the end regarding the bushing retaining plate.

The shifter is mostly installed at this point. I knocked the razor's edges off of the base plate with a sanding block which was good enough for me.

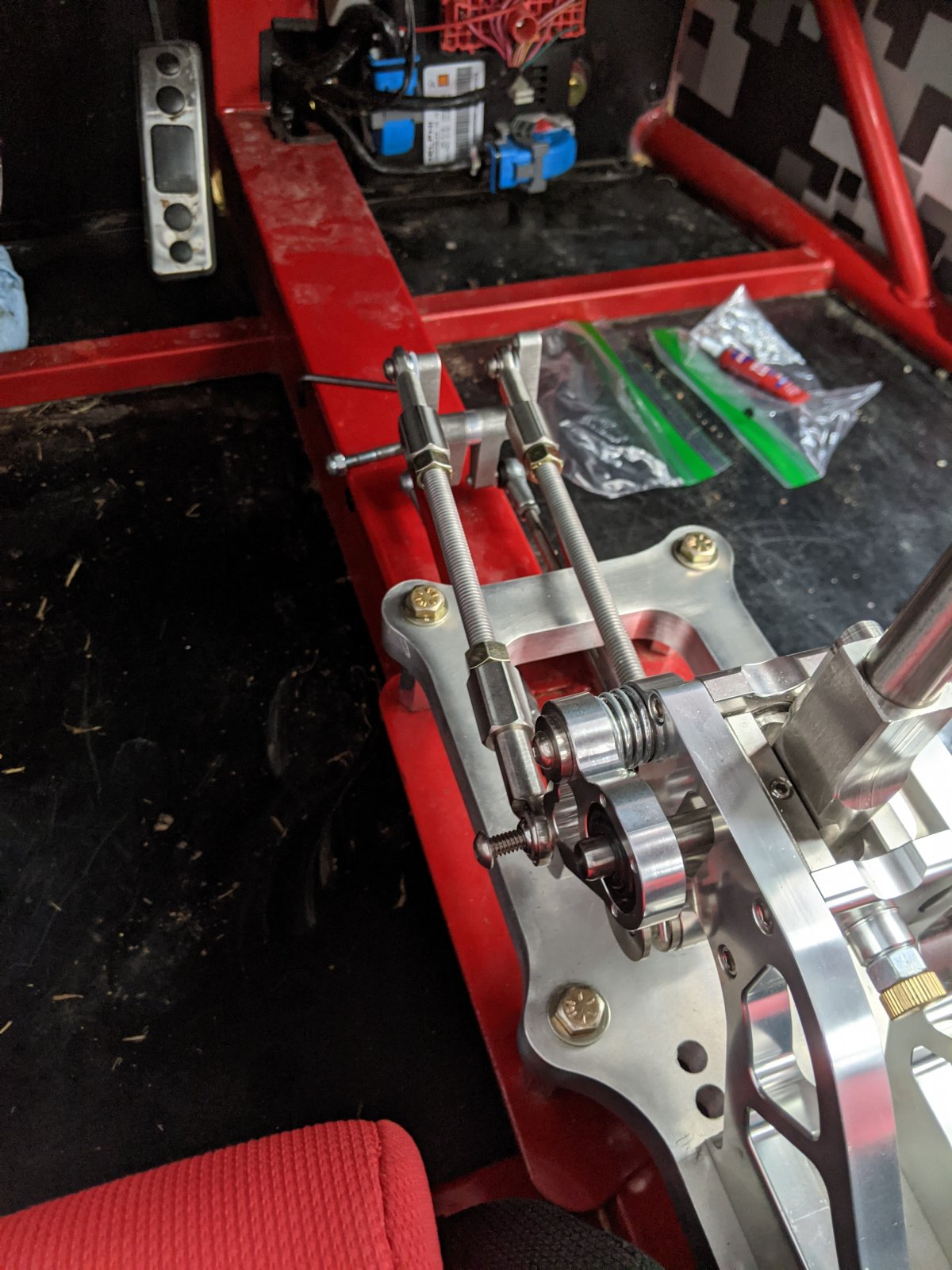

Mounting the baseplate and shifter itself was trivial. Trying to get the rods and cables adjusted correctly has required a lot of trial and error. If there's a way to do it without removing one of the linkage rod ends everytime, I'm too dense to figure it out.

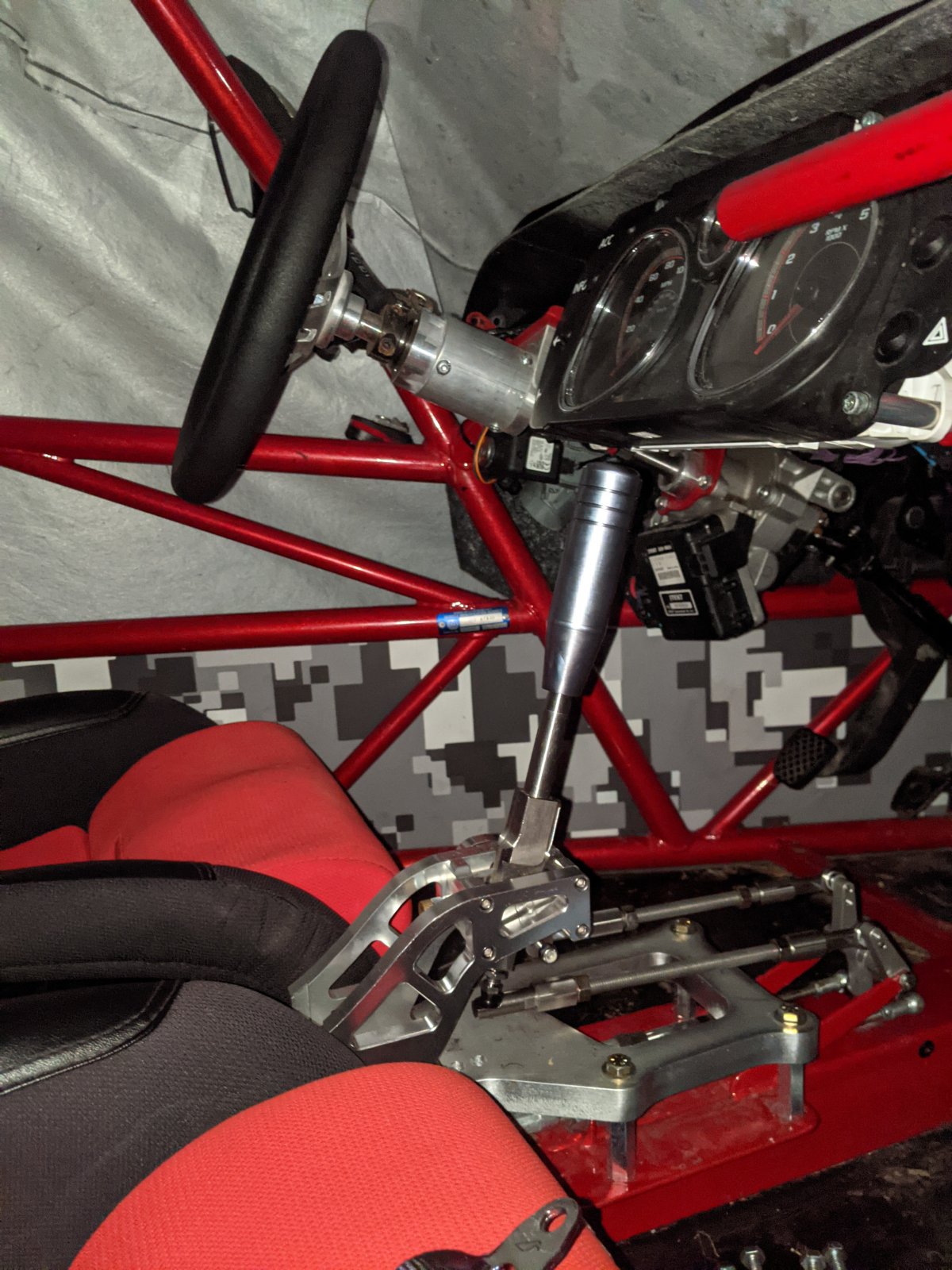

Forward/backward throw feels good and was easy to get right- really it could use an even shorter throw than what's afforded by backing the bolt at the bottom of the lever out as far as is reasonable and attaching the other end of the rod to the short hole of the bell crank, but it's good as is. The only problem is that even mounted to the rearmost mounting holes on the baseplate I can still bust my knuckles on the gauges on a forward throw with a 5" shift knob. I'm probably going to end up cutting about half an inch off of the lever to make room if I want to keep the long shift knob. I don't really want to cut the lever but it seems necessary. Pic below is the room that was provided after I destroyed one of the thread adapters trying to get the knob lower and it still wasn't quite enough.

Left/right throw was a pain to work out. I started with the bell cranks straight up and down but found that I couldn't reach reverse at all, so I put the car in reverse and worked backwards from there which worked pretty well. I had to tighten the linkage arm down to make it as short as possible even with the shifter set back all the way on the mounting plate. Any farther forward and the threaded rod would have to be cut. I like the size of tighter pattern afforded by using the longer portion of the arm on the shifter and the shorter portion of the arm on the bell crank, but the amount of resistance makes this rather impractical so I'll likely swap one or both mounting points and deal with the additional left/right throw distance. As an aside, I've seen where folks have mounted up their left side linkage rods to the inside of the arm on the shifter which looks better and provides a more linear push/pull, but the rod end ends up interfering and binding with the shifter in that configuration.

It looks like I might be able to drop in a washer or two on the shift lever pivot to tighten things up so I'm probably going disassemble and give that a try.

Something I ran into along the way that is a bit concerning- it appears that the threads for the pivot bolt for the reversers has wallowed out some of the metal causing some slop. There wasn't much metal here to begin with and there's less now. I don't know what to do to fix this other than weld in or bolt on more material in place. This area could have benefitted from additional material on all axes and/or enough room for some bushings or a sleeve for the bolt to run through.

Finally, the biggest problem that I've run into- the retaining plate and hardware for the spherical bushing on the left hand side of the shifter didn't make its way into the box that I received. When and where it was lost is anyone's guess at this point. I've contacted SACTX and the original owner in hopes that I can find the original or a replacement, and I've got several bags and boxes of miscellaneous hardware that came with the car that I'm going to go through a 3rd time, but I'm kind of up a creek without it as the bushing pops out after a few shifts. I'm trying to figure out how to fashion a stopgap in the meantime. It's rough, but I'm thinking a couple of o-rings may be enough to keep things in place until I can find the proper part.