Ross's extended city, easy entry Goblin- 06 SS/SC, NW Arkansas

- Thread starter Ross

- Start date

Ross

Goblin Guru

I agree, too much vibration in my mickey mouse tripod. but the point was to stay directly over the A arm to see if it is flexing. I think the reference red dots did show a small amount of flexing. This camera angle is trying to stay directly on top of the A arm, and not be changed by suspension movements and caster changes.

Last edited:

Ross

Goblin Guru

So there is a little more than 1/8" gap at the front, if you hold the level tight against the mid section. Same on both sides. I consider this normal weld shrinkage unless everyone else's frames are straight.

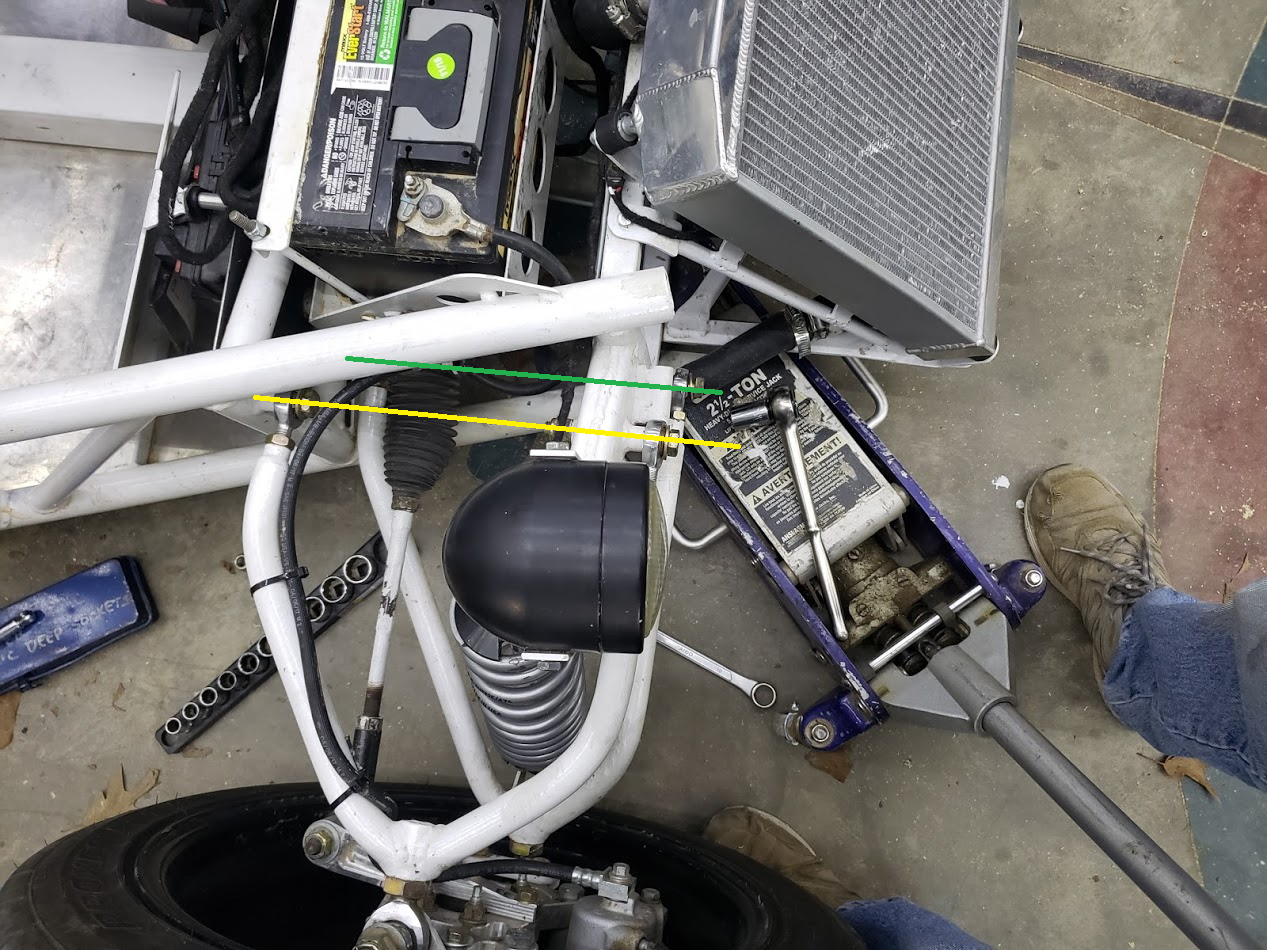

Brian - If the lower A arms pivot (green line) is parallel to the upper A arms pivot (yellow line) then there shouldn't be any caster change during suspension movement. I thought the Goblin had an angle between these pivots, but I am not seeing it now... so I was wrong. Wow! That means all the movement I am seeing in my billet uprights is flex! Yikes!

Brian - If the lower A arms pivot (green line) is parallel to the upper A arms pivot (yellow line) then there shouldn't be any caster change during suspension movement. I thought the Goblin had an angle between these pivots, but I am not seeing it now... so I was wrong. Wow! That means all the movement I am seeing in my billet uprights is flex! Yikes!

Brian74

Goblin Guru

The only way you can confirm it is a geometry issue and not flex, is by pulling the wheel and spring and verifying that the caster is not changing under suspension travel, and then doing some further measuring.

youtube.com

youtube.com

Get rid of the road camera & check the simple stuff first. If something is bent, measured wrong, or misaligned; this is the only way that you will find it.

- YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Get rid of the road camera & check the simple stuff first. If something is bent, measured wrong, or misaligned; this is the only way that you will find it.

Last edited:

ATMironov

Well-Known Member

Some times you can get wheel hop from a warped rotor, or potentially a bad brake pad transfer layer.

Did you use the donor rotors or new ones?

Could you take a closeup photo of one of the rotors and post it?

It might be worth popping out the brake pads too to make sure they haven’t separated from the backing plates.

This all seems unlikely, but at this point leave no stone unturned.

Did you use the donor rotors or new ones?

Could you take a closeup photo of one of the rotors and post it?

It might be worth popping out the brake pads too to make sure they haven’t separated from the backing plates.

This all seems unlikely, but at this point leave no stone unturned.

Ross

Goblin Guru

Thanks everyone for your feedback, and input, to this perplexing (for me) issue. Yeah, I think I am past the road camera too. I was hoping to find the issue with a camera, but I'm ready to spend $5 of welding gas, and a few hours of my time, to try to fix it will an additional bar on the A arms. If it doesn't fix it, I'll keep looking elsewhere. Stay tuned for the next update!

I am doing the road camera because I am past the simple stuff.

I just had a wheel alignment, and it is within the specifications that I have.

Visual frame inspection is done, it looks slightly bent, like everything I have ever welded.

Slightly bent in a good way, symmetrically, and at the weld points where it should be bent. Same on both sides.

Please correct me if I am wrong, but if you visually inspect your frame, is it not slightly bent too?

How much bend is too much? I don't know, unless someone else has measured their frame to compare too.

Yes, wheel hop can come from warped rotors, or straight rotors with uneven surface friction. Those conditions you can normally feel the brakes pulsing at slow RPMs. But those conditions would not cause caster changes while braking. Once I fix that, then we will see if there is any wheel hopping left.

I am doing the road camera because I am past the simple stuff.

I just had a wheel alignment, and it is within the specifications that I have.

Visual frame inspection is done, it looks slightly bent, like everything I have ever welded.

Slightly bent in a good way, symmetrically, and at the weld points where it should be bent. Same on both sides.

Please correct me if I am wrong, but if you visually inspect your frame, is it not slightly bent too?

How much bend is too much? I don't know, unless someone else has measured their frame to compare too.

Yes, wheel hop can come from warped rotors, or straight rotors with uneven surface friction. Those conditions you can normally feel the brakes pulsing at slow RPMs. But those conditions would not cause caster changes while braking. Once I fix that, then we will see if there is any wheel hopping left.

Brian74

Goblin Guru

Let me know if you need any more videos or specific measurements. I’ll have this thing mocked up for at least another week.Oh, Brian, thanks for your video. I will do that test when I take apart the suspension... and video record it.

Glad you made me re-think my position on caster changing while suspension is moving.

Desert Sasqwatch

Bigfoot Goblin

Ross, I can confirm the lower frame tube is not perfectly straight. From the front edge (radiator hose opening) back to the double frame cross brace (extended frame) I have about 3/16 gap, with the 'high point' at the front suspension cross bracing at the forward firewall - if that makes sense.Brian74 & Desert Sasq - I looked down my 4 main frame rails, and there is some curvature at the weld points, like I expected, from weld shrinkage. I'm curious if your frame has this too. Mostly on the bottom 2 rails.

Rauq - The snapped steering arm was replaced. I replaced both sides, as DF comp'd me the parts, as they were out of the AT solid design, so I am back with scalloped parts. Both sides probably had metal fatigue.

Andrew - not yet. I am more concerned about the movement in the billet uprights before the hopping occurs. Whether the rotors are out of true or not, the uprights shouldn't have flex. I think if I fix the flexing, then the hopping will stop. If I'm wrong and still have hopping, I will start checking things like brake rotors.

Waterdriver - I agree, the last video made me think the upper A arm was flexing. I also was concerned about the amount of threads showing on that heim. The bottom heims are tucked in already, and the top still needs extra length. I could transfer some of those threads over to the wheel end of the A arm, but it too is threaded out quite a ways. I figured it was pretty evenly balanced between the 2 sides, but I need to check for movement there. The car brakes nice and straight, and only shudders if I press too hard. I noticed today that as I slow down speed, I can brake more without hopping.

I will see if today's video sheds any light on the issue. I concentrated on the upper A arm today.

I did some red neck engineering, and used 3 sticks of wood to make a tripod that holds a camera directly over the upper A arm.

Also have a GoPro on the upper frame rail. I will do some video editing, and see if I get some new clues.

View attachment 22605

Sounds like your frame is still geometrically the same as it was welded up on the DF jig.

Waterdriver

Goblin Guru

I'm guessing your going this route with a tube between the arms?

Exocet V8 upper arms.

It still seems weird that nobody else has had this same issue. Seems like we're missing something here.

Exocet V8 upper arms.

It still seems weird that nobody else has had this same issue. Seems like we're missing something here.

Ross

Goblin Guru

Something like that. We have the shock support in the middle, so we have to get creative.

I did propose some designs here, but I think I will keep it simpler, and only add one bar instead of two.

I don't know if this is the issue.. but I am willing to try it.

I will inspect the current A arms for cracks, stripped threads, loose threads, worn heim joints, etc.

I did propose some designs here, but I think I will keep it simpler, and only add one bar instead of two.

I don't know if this is the issue.. but I am willing to try it.

I will inspect the current A arms for cracks, stripped threads, loose threads, worn heim joints, etc.

Desert Sasqwatch

Bigfoot Goblin

You will need some speedholes in those so they don't slow you down!

ctuinstra

Goblin Guru

No! It’s aero!You will need some speedholes in those so they don't slow you down!

Ross

Goblin Guru

Dale E. drove 5+ hours yesterday to come help me with the braking issue. Wow, how generous!

For the last day and a half we have been testing and eliminating possible issues.

We found a solution that doesn't wheel hop when braking:

Those temporary tires only skid when braking. Skid pretty easily too. 3" wide tires on the front looks pretty silly, but I kind of wanted to try it with the 12.5" tires on the rear.

Put the Cobalt tires back on the goblin, it wheel hops when braking at 40+ mph, but skids below that speed.

Put the normal 275 Proxes back on, it wheel hops at any speed.

We started with the ride height, correctly weighted the goblin with 330 lbs ballast, lowered the passenger side a bit. Corrected the camber on the front passenger side, Took it for a test drive. Wheel hop, but better wheel alignment.

Checked the wheels & frame for balance - is one wheel further forward? Does the frame look bent? Anything not symmetrical? Did measuring, checked with levels, angle finders, digital angle finders. Seems good.

Checked for bump steer. We moved the billet arm up and down, and discovered the lower we put the tie rod end, the less the bump steer. Dale also taught me how to correct bump steer by using a bump steer kit like this one (example only, that one isn't specific for the Cobalt).

Swapped out the 1/4" thick elbows for the 3/8" thick ones on the uprights.

Checked the front brake rotors for warpage. They are good.

Checked the tow in on the front. 3/16" is good.

Checked the caster. 6 degrees is good.

Running out of ideas how to fix the hopping, I decided to weld on gussets on the A arms.

Chad, you are right, these gussets are aero. Aero only. The gussets made no difference, still wheel hopping while braking.

Checked the rear tires for tow-in. They were crab walking a little, so we adjusted the rear tow in. Still hopping.

Swapped the front brake pads out for the ones on my 2nd donor car. Still hopping.

We tried different brake bias, could skid the rears, or can hop the fronts.

We tried different shock settings. Still hopping.

We tried 5 degrees caster. Hopping.

Checked the wheel for any slop, and on further scrutiny, the passenger upper heim joint has a little movement.

Need to try a new heim joint. The other heim joints seem tight, but maybe buy all new ones, as I am running low on ideas on what to try.

We eliminated a lot of things that could be causing it, but still haven't isolated the exact cause of my special wheel hop issue. Autocross is 1.5 weeks away, can I solve this 2 year mystery?

For the last day and a half we have been testing and eliminating possible issues.

We found a solution that doesn't wheel hop when braking:

Those temporary tires only skid when braking. Skid pretty easily too. 3" wide tires on the front looks pretty silly, but I kind of wanted to try it with the 12.5" tires on the rear.

Put the Cobalt tires back on the goblin, it wheel hops when braking at 40+ mph, but skids below that speed.

Put the normal 275 Proxes back on, it wheel hops at any speed.

We started with the ride height, correctly weighted the goblin with 330 lbs ballast, lowered the passenger side a bit. Corrected the camber on the front passenger side, Took it for a test drive. Wheel hop, but better wheel alignment.

Checked the wheels & frame for balance - is one wheel further forward? Does the frame look bent? Anything not symmetrical? Did measuring, checked with levels, angle finders, digital angle finders. Seems good.

Checked for bump steer. We moved the billet arm up and down, and discovered the lower we put the tie rod end, the less the bump steer. Dale also taught me how to correct bump steer by using a bump steer kit like this one (example only, that one isn't specific for the Cobalt).

Swapped out the 1/4" thick elbows for the 3/8" thick ones on the uprights.

Checked the front brake rotors for warpage. They are good.

Checked the tow in on the front. 3/16" is good.

Checked the caster. 6 degrees is good.

Running out of ideas how to fix the hopping, I decided to weld on gussets on the A arms.

Chad, you are right, these gussets are aero. Aero only. The gussets made no difference, still wheel hopping while braking.

Checked the rear tires for tow-in. They were crab walking a little, so we adjusted the rear tow in. Still hopping.

Swapped the front brake pads out for the ones on my 2nd donor car. Still hopping.

We tried different brake bias, could skid the rears, or can hop the fronts.

We tried different shock settings. Still hopping.

We tried 5 degrees caster. Hopping.

Checked the wheel for any slop, and on further scrutiny, the passenger upper heim joint has a little movement.

Need to try a new heim joint. The other heim joints seem tight, but maybe buy all new ones, as I am running low on ideas on what to try.

We eliminated a lot of things that could be causing it, but still haven't isolated the exact cause of my special wheel hop issue. Autocross is 1.5 weeks away, can I solve this 2 year mystery?

Do both front tire wheel hop?

Do the wheel hop equally?

Is the wheel hopping timed from left tire to right tire causing the steering wheel to shake left to right or do you feel the hopping is independent of the other tire?

Have you tried a new set of brake rotors?

If you push and pull on the top of the tire can you feel any play in your bearing hubs?

New bearing hubs and rotors are two things that I strongly feel should be swapped as a test even if you can not see a problem with them.

I would try bearing hubs first, I feel like you would feel pulsing in the brake pedal, car, and steering wheel if a rotor had a problem.

Have you tried bleeding the brakes and is there a possibility that your master cylinder has a problem that is causing reverberating feedback to the calipers.

I know the master cylinder has two separate pistons inside and uses one to actuate the other, maybe there is a communication problem between them.

I believe the only way to make forward progress at this point is to start replacing parts.

Do the wheel hop equally?

Is the wheel hopping timed from left tire to right tire causing the steering wheel to shake left to right or do you feel the hopping is independent of the other tire?

Have you tried a new set of brake rotors?

If you push and pull on the top of the tire can you feel any play in your bearing hubs?

New bearing hubs and rotors are two things that I strongly feel should be swapped as a test even if you can not see a problem with them.

I would try bearing hubs first, I feel like you would feel pulsing in the brake pedal, car, and steering wheel if a rotor had a problem.

Have you tried bleeding the brakes and is there a possibility that your master cylinder has a problem that is causing reverberating feedback to the calipers.

I know the master cylinder has two separate pistons inside and uses one to actuate the other, maybe there is a communication problem between them.

I believe the only way to make forward progress at this point is to start replacing parts.